Electromagnetic components

Magnetbau Schramme develops customised electromagnetic components and special electromagnets and produces them in series. You can rely on our many years of experience and expertise to make your project a success.

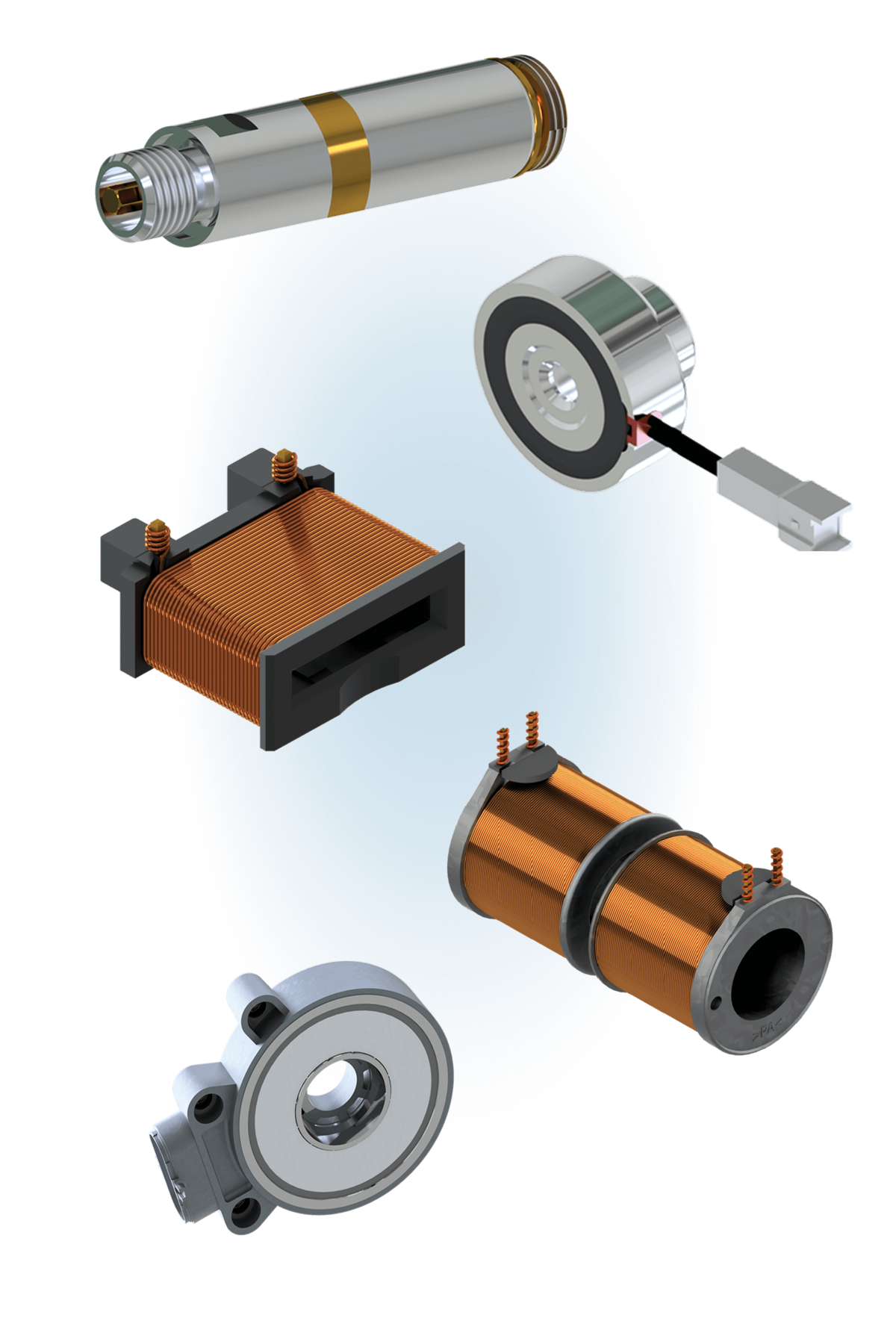

Discover a diverse selection of different electromagnetic components and special electromagnets below.

Electromagnet components and special electromagnets - Product details

Advantages & structure of electromagnet components and special electromagnets

Magnetbau Schramme has been developing and producing electromagnet components and special electromagnets in small and large series for a wide range of applications and industries for over fifty years.

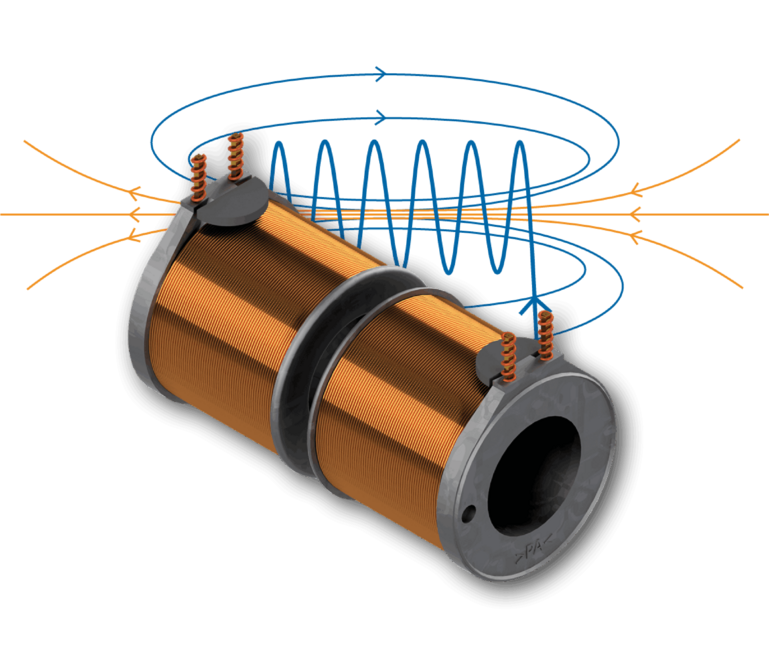

These special solenoid solutions are mainly used as functional components to generate linear or rotary movements in various assemblies and systems.

Electromagnet components and special electromagnets are indispensable elements in modern drive technology and automation. Magnetbau Schramme offers a wide range of specialised solutions for demanding industrial applications.

Electromagnetic clutches enable the precise and contactless connection and disconnection of shafts, ensuring controlled power transmission. Electromagnetic brakes ensure the exact and safe deceleration of movements as well as precise positioning, which is particularly important for mechanical engineering. The solenoid coils generate defined magnetic fields that can be flexibly adapted as central components in various applications, for example in actuators or sensors. Actuation systems control movements with high precision and enable smooth processes in automation through linear or rotary actuators. In addition, magnetic bearings provide low-friction and virtually wear-free support for rotating components, significantly increasing the efficiency and service life of the systems.

Please note

Please note that we do not have any standard products. The following electromagnet components and special electromagnets are merely examples of customer projects realised in series production.

Electromagnetic components: Industries

Our industry diversity

Electromagnet components and special electromagnets from Magnetbau Schramme are used in numerous industries. In the automotive industry , they enable the realisation of precise control systems and actuators, while in medical technology they are crucial for reliable movements and positioning. In mechanical engineering , they offer durable solutions for drive systems and couplings. They are also used in the aerospace industry, where maximum precision and reliability are required, and in energy and environmental technology for the control and regulation of complex processes.

Our management system according to ISO 9001 & IATF 16949 supports us in ensuring the quality requirements during the development & production of electromagnet components.

Marco Kiene

Management | CSO

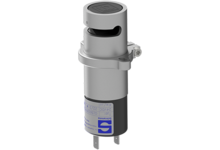

Valve solenoid application example

Steering axle for commercial vehicles

A valve solenoid in the valve block of a trailer steering axle controls precise hydraulic valves that regulate the flow of hydraulic oil.

It ensures optimum steering assistance by adjusting the actuating force of the steering depending on the speed. This results, for example, in smooth steering at low speeds and steering stability at higher vehicle speeds. In addition, the valve solenoid supports safety and assistance systems, making steering more efficient, precise and fail-safe.

More information about electromagnetic components

Magnetbau Schramme offers a wide range of customisation options to adapt electromagnetic products and special electromagnets precisely to the specific requirements of its customers or to develop them on this basis. Our decades of experience and expertise enable us to make adjustments in size, shape, magnetic force and control so that the solenoid components can be optimally integrated into existing systems. Typical variables include the customisation of electrical parameters, special mounting options and precisely coordinated energy efficiency. Magnetbau Schramme also takes into account special operating conditions such as extreme temperatures, high mechanical loads or special safety requirements in order to always guarantee the ideal solution.

Another important factor is the high precision and adherence to tight tolerances during production. State-of-the-art production techniques and strict quality controls guarantee minimal deviations; a decisive advantage in demanding industries such as medical technology and robotics. Precise control of the magnetic field strength and adjustment options ensure maximum accuracy in every application. Customised precision requirements can also be implemented, for example for applications that require the most precise movements and forces. Magnetbau Schramme thus ensures that its products meet the highest standards of accuracy and reliability.

To ensure the service life and reliability of the electromagnet components, Magnetbau Schramme carries out comprehensive tests and inspections. These include load tests, temperature cycling tests and corrosion tests, which guarantee the resistance of the components under extreme conditions.

These tests are essential in order to guarantee the highest quality and durability for various areas of application. Strict adherence to quality standards and continuous documentation of all tests give customers the certainty of receiving durable and robust products.

Magnetbau Schramme also relies on innovative materials and modern production technologies to ensure optimum performance and efficiency at all times. The use of highly conductive alloys and heat-resistant materials is particularly crucial in demanding environments. Advanced technologies such as 3D printing enable complex geometries and customised shapes that were previously almost impossible to implement. These developments are leading to more compact, more powerful and more energy-efficient magnetic components. By using the latest technologies, Magnetbau Schramme remains competitive and offers future-oriented solutions that optimally fulfil the growing technical requirements of customers.

Electromagnetic components - Questions & Answers

What special customisation options does Magnetbau Schramme offer for customer-specific electromagnets?

Magnetbau Schramme offers extensive customisation options to tailor electromagnets precisely to the needs of its customers. This includes flexible modifications to size, shape, magnetic force and control. The operating voltage and mounting options can also be customised. Magnetbau Schramme also takes into account special requirements such as extreme temperatures, high mechanical loads or special safety standards. Customised solutions, which are closely coordinated with the customer, result in a product that is technically perfectly tailored to the respective application.

How are precision and tight tolerances ensured in the production of magnetic components?

To ensure high precision and tight tolerances, Magnetbau Schramme utilises state-of-the-art production techniques and strict quality controls. Computer-aided production processes minimise deviations, which are particularly important for sensitive electromagnetic components. This enables Magnetbau Schramme to offer its customers products that fulfil even the most demanding accuracy requirements and guarantee reliable performance in critical applications.

What innovations are there in the field of electromagnet components?

There are exciting innovations in the field of electromagnet components, such as the use of new materials (e.g. highly conductive alloys) and heat-resistant plastics, which enable higher performance and robustness. In addition, additive manufacturing techniques such as 3D printing allow the production of complex geometries and customised shapes that were previously almost impossible to realise. Advances in microelectronics enable more precise control and integration of sensor technology, which further increases the efficiency and range of applications for electromagnets, particularly in automation and robotics.

Which industries particularly benefit from the special electromagnet solutions from Magnetbau Schramme?

Special electromagnets from Magnetbau Schramme are used in a wide range of applications in industries with high technical requirements. These include medical technology, the automotive industry, aerospace and automation technology. These sectors require solenoid solutions that can withstand extreme conditions and enable precise control. Thanks to customised electromagnets that are specifically tailored to demanding applications, customers from these sectors benefit from durable, powerful and reliable magnetic components that optimally support their system requirements.