Rapid development, validation & industrialisation.

Actuation systems

Are you looking for a reliable partner for high-quality actuation systems / solenoid tubes? Then you've come to the right place! As a specialist in the development and production of customised actuation systems, we offer you innovative and precise solutions that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of actuation systems / solenoid tubes

Our performance and expertise. Your success.

Magnetbau Schramme is your trusted partner for the development and series production of actuation systems. Thanks to our technical expertise and many years of experience, we offer customised solutions that are optimally tailored to your specific requirements. From the initial idea to series production, we are at your side and ensure a smooth process at every stage of development.

Contact us today and let our experts advise you individually.

Please note!

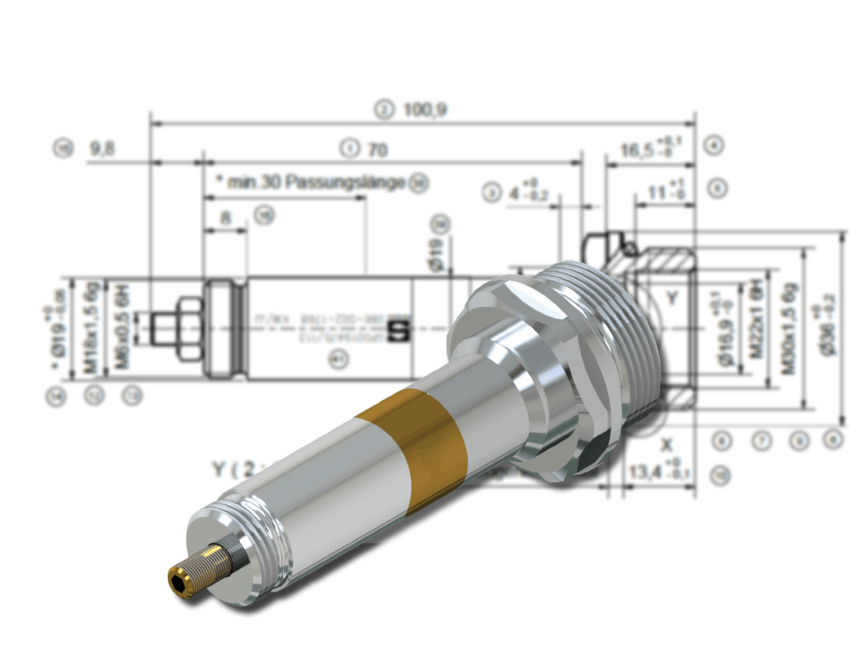

Please note that we do not have any standard products. The following actuation systems are merely examples of customer projects realised in series production.

Technical data - Actuation systems

Experience the wealth of different possibilities.

Actuation systems / solenoid tubes are mechanical elements that help to convert electrical signals into precise linear movements and are used to control valves, switches or other components. They are characterised by their high reliability, robust design and long service life, which makes them ideal for industrial and automated applications.

Do you have any questions about our technical data or other details you would like to discuss? Please do not hesitate to contact us.

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised actuation systems / solenoid tubes and further solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

Further information about actuation systems

How actuating systems work

- An actuating system is an elementary component of an electromagnet. In the actuating system, the magnetic force is turned into a mechanical movement to control components such as valves, switches or flaps.

- A ferromagnetic armature moves towards a core. This linear movement opens or closes mechanical valves or switches systems. Feedback is provided by a spring or other restoring force as soon as the current is switched off.

- Actuation systems offer precise, reliable properties and are optimised for industrial applications as they enable fast, repeatable control of fluid or mechanical processes.

Designs and types of actuation systems

- Actuation systems usually have a round design and can therefore fulfil specific technical requirements. The main design element is the working air gap and the so-called "magnetic separation". An actuation system cannot function without these two elements. So what may look inconspicuous is actually a sophisticated and well-engineered product with a fundamental effect on the function of an overall system.

Performance parameters Actuation systems

- Force: This is the mechanical force that the actuation system generates to perform an action, such as moving a valve. In an electromagnetic actuation system, the force depends on the current strength and the magnetic field strength, but also on the design of the actuation system.

- Pressure resistance: the ability of an actuation system to withstand a certain pressure load without permanent deformation or destruction. Pressure resistance is a decisive parameter for assessing the stability and safety of actuation systems and their applications.

- Stroke: The stroke describes the maximum linear movement of the armature within the actuation system. This parameter is crucial as it determines how far a valve or component can be opened or closed.

- Reaction time: The reaction time of a solenoid system indicates how quickly it starts to move after an electrical signal, i.e. how long it takes for the system to be fully activated. It depends, among other things, on the design of the actuation system and the materials used.

Construction of the actuation system

- Pressure tube / housing: A robust pressure tube that protects the system and provides the mechanical structure. It is made of metal and is adapted according to the requirements for mechanical load capacity, pressurisation and ambient conditions.

- Armature: The armature is a ferromagnetic component positioned in the centre of the actuator. The armature is moved by the magnetic attraction, which triggers a mechanical action. The armature usually moves linearly, but can rotate within certain actuators ("rotary armature"), depending on the design of the system.

- Spring mechanism: Many actuation systems use a spring to return the armature to its initial position after the current is switched off. This ensures that the armature position is never left to chance.

Applications Actuation system

- Valve control: Actuation systems are used in hydraulic and pneumatic valves to precisely control the flow of liquids or gases. They are essential in industrial areas such as stationary or mobile hydraulics.

- Automation technology: In automated production plants, actuators with actuation systems control mechanical movements, for example in robots, pick-and-place systems or conveyor belts. They ensure that processes run quickly and precisely and increase efficiency and safety in manufacturing and assembly processes.

- Vehicle technology: In modern vehicles, actuators with actuation systems can be used for numerous applications. The control of brakes, clutches or gearboxes can be such applications. They contribute to vehicle automation and driving comfort and increase the safety and efficiency of vehicle systems.

Environmental requirements Actuation system

- Actuation systems must fulfil strict environmental requirements, such as resistance to extreme temperatures, moisture, dust and corrosion. They must also be resistant to vibration and impact, especially in harsh industrial or mobile applications. In addition, protection classes such as IP67 or higher are often required to ensure impermeability to water and dust. Environmentally friendly materials and energy-efficient designs are increasingly important requirements in the development of modern systems.

Actuation system - Questions & Answers

What is the difference between an actuation system and an excitation system?

Actuation systems and excitation systems are closely linked, especially in electromagnetic applications. The excitation system generates a strong magnetic field, which forms the basis for the operation of the actuation system. This magnetic field is used in the actuation system to generate a mechanical movement, such as switching a valve or moving a piston. A typical example is an electromagnetic valve where the excitation system provides the magnetic field and the actuation system uses it to open or close the valve. Without the excitation system, the actuation system would not be able to perform the necessary mechanical movement. Both systems therefore work together to convert electrical energy into precise mechanical actions.

How do you test an actuation system?

An actuation system is tested for functionality and reliability using various tests. These include mechanical function tests in which the movement sequence and force development of the system are tested. Furthermore, tightness and pressure resistance are often parameters that are defined and tested 100% end-of-line. In addition, environmental and endurance tests are often carried out to ensure that the system works reliably even under extreme conditions such as temperature, humidity or vibrations.

What is an excitation system?

An excitation system generates the magnetic field required to operate electrical machines such as actuators or electromagnet systems. Energising the coil contained in the excitation system creates the magnetic field required to generate force and stroke in electromagnet systems.

What is the purpose of the actuation system?

The actuation system is used to convert a magnetic field into reproducible mechanical movements in order to trigger specific actions in a technical system. It is often used to control components such as valves, switches or levers, for example by opening or closing valves, activating electrical circuits or executing mechanical movements in machines. The system thus enables precise control of sequences in automated processes, machines or vehicles.

What pressures can actuation systems withstand?

Actuation systems are designed for different pressure ranges, depending on the design. High-pressure actuation systems can withstand pressures of well over 1000 bar and more, as found in hydraulic applications or industrial high-pressure systems. Low-pressure actuation systems, on the other hand, are designed for pressures up to around 50 bar and are often used in pneumatic systems or for controlling fluids at lower pressures. The specific pressure resistance depends on the design, materials and sealing technology.

How is the actuation system attached to the valve block?

The actuation system is usually attached to the valve block using screw connections or clamping devices. In many systems, the actuation system is placed directly on a suitable mounting flange on the valve block and fixed with screws to ensure a stable and tight connection. In addition, O-rings or other seals ensure that there are no leaks between the actuation system and the valve block. In some cases, a special bayonet mounting or a snap-on connection can be used to enable quick and tool-free assembly.