Rapid development, validation & industrialisation.

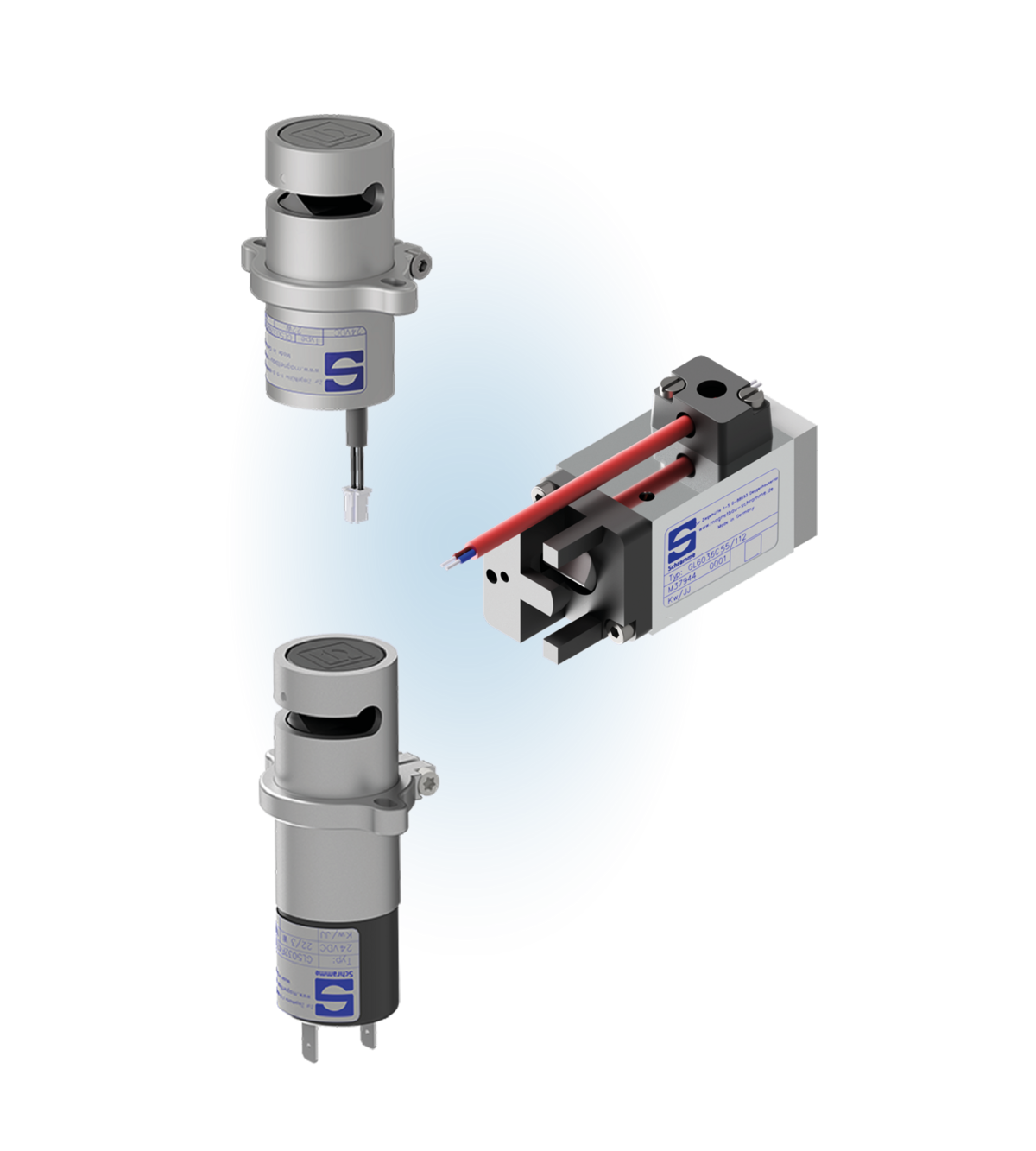

Pinch valves

Are you looking for a reliable partner for high-quality pinch valves? You've come to the right place! As a specialist in the development and production of customised pinch valves, we offer you innovative and precise solutions that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of pinch valves

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of pinch valves. With our technical expertise and many years of experience, we realise individual solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure that everything runs smoothly at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

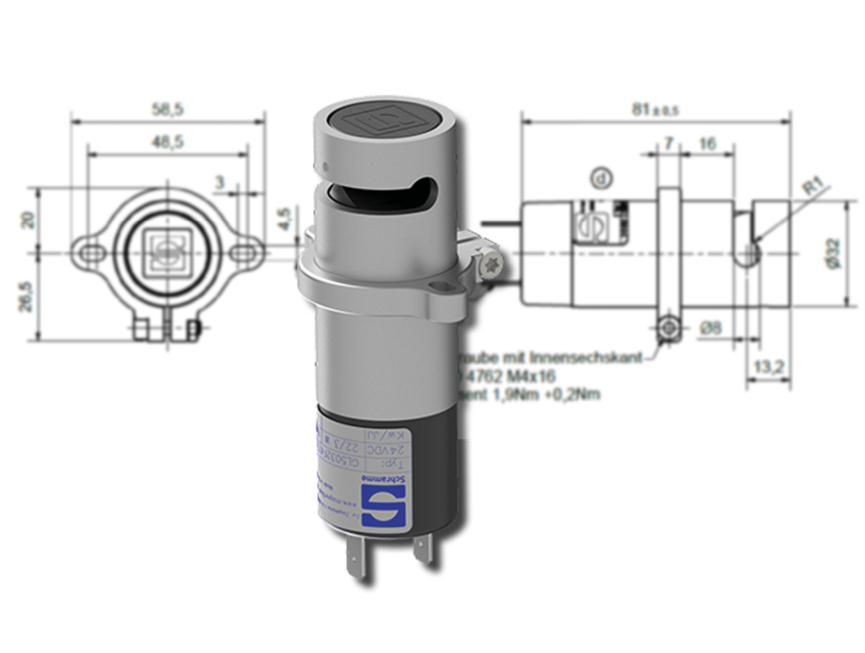

Please note that we do not have any standard products. The following pinch valves are merely examples of customer projects realised in series production.

Technical data - Pinch valves

Experience plenty of different possibilities.

A pinch valve is a flow control valve that controls the flow of liquids or gases through flexible hoses by mechanically clamping the hose. Instead of blocking the flow directly, the tubing is compressed at a specific point, allowing for easy and contamination-free flow control. These valves are often used in areas where sterile or particle-free work is required, such as in medical technology or the food industry.

Do you have any questions about our technical data or other details you would like to discuss? Please do not hesitate to contact us.

| Sizes / types | No limitation, up to a max. construction weight of 15kg |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Hose diameter | 5mm to 10mm |

| Protection class / protection type | IP6K9K |

| Electrical connection | Free stranded wires, surface-mounted connectors, integrated (moulded) connectors, etc. |

| Special features | Integrated peak and hold electronics, optimised clamping wedge geometry, Normally Closed and Normally Open |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised pinch valves and further solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about pinch valves

How a pinch valve works

A pinch valve controls the flow of liquids or gases by mechanically clamping a flexible hose. The clamp or a movable element is actuated electromagnetically to compress the hose and regulate or stop the flow. As the medium does not touch the valve body, the contents of the hose remain protected from contamination, which is particularly advantageous in hygienic applications.

- Clamping mechanism: The centrepiece of the valve is a movable element, usually a piston or a wedge-shaped pinch jaw, which compresses the flexible hose from the outside. This element is actuated by an electromagnetic actuator.

- Actuator: The actuator generates a linear movement that moves the clamping mechanism towards the hose. Actuation squeezes the hose at the desired point. Depending on the strength of the pinch-off pressure, the flow can either be stopped completely or precisely regulated. The actuator can be designed either normally closed or normally open.

- Reset mechanism: For valves that need to be reopened, a spring mechanism or counterforce is used to return the clamping mechanism to its original position after actuation, releasing the hose and restoring the flow. In de-energised closed versions, the media flow in the hose is stopped in the de-energised starting position.

Designs and types of pinch valves

- Pinch valves with rectangular housing: These valves have a rectangular cross-section and are ideal for applications with limited space due to their compact design. They can be easily integrated into various customer applications and offer reliable clamping mechanisms for precise flow control.

- Round body hose clamp valves: These valves have a cylindrical cross-section and are often more cost-effective as they can potentially be manufactured with simpler body components.

Performance parameters pinch valves

- Nominal pressure: The nominal operating pressure of the medium flowing through the hose without damaging the hose or valve. This can vary depending on the valve type and hose material.

- Hose diameter: The supported outer diameter of the hose that the valve can clamp influences the flow rate and the application areas.

- Flow rate: The maximum amount of medium that the valve allows to pass through the hose when open, measured in litres per minute (L/min).

- Clamping force: The force exerted by the valve on the hose to reliably push it off so that the flow is safely stopped or regulated.

- Media compatibility: The valve must be suitable for the medium (e.g. liquids, gases, aggressive chemicals) without causing corrosion or damage to the hose or valve components.

Structure of the pinch valve

- Valve housing: The housing encloses the internal mechanics of the valve and protects them from external influences. It is often made of metal or robust plastic to withstand mechanical stress and environmental conditions.

- Coil: In electrically actuated valves, the coil converts electrical energy into magnetic energy. It generates an electromagnetic field that activates the clamping mechanism to squeeze or open the hose. The coil enables precise and fast control of the valve.

- Clamping mechanism: The core of the valve, consisting of a movable element (e.g. a clamp, piston or jaw) that squeezes the hose to regulate the flow. The clamp mechanism can be moved to different positions to partially or fully squeeze the hose.

- Actuator: The actuator controls the clamping mechanism. It ensures that the clamping mechanism squeezes the hose in the desired way.

- Hose holder: A guide or holder for the flexible hose that ensures that the hose remains correctly positioned and fixed while the clamping mechanism is working.

- Seals: Additional seals are integrated into many valves to prevent liquids or gases from entering the valve body and affecting the internal mechanism.

- Return spring: In spring-loaded valves, a return spring ensures that the clamping mechanism returns to its original position after the actuator is released or switched off.

Applications pinch valve

- Medical technology: Tube clamp valves are often used in infusion and transfusion units to control the flow of fluids or medication. They ensure precise dosing and minimise the risk of contamination.

- Food and beverage industry: In food production and beverage filling, hose clamp valves are crucial to ensure hygienic standards. They prevent contamination during the transport of liquids and enable precise control of the flow.

- Chemical industry: In the processing of chemical substances, pinch valves are used to control the flow of aggressive media. They offer safe handling and prevent leaks.

- Laboratory applications: In laboratories, pinch valves are used in experiments and analyses where precise control of media flow is required, such as when handling chemicals or biological samples.

- Automation technology: In automated processes, pinch valves are used to integrate flow control into machines and systems. They allow the flow rate to be adjusted in real time and support the efficiency of production lines.

- Pharmaceutical industry: Pinch valves are important in pharmaceutical production, where they are used to handle solutions, suspensions and other pharmaceutical products. Their ability to regulate the flow hygienically is of great importance here.

Control and regulation pinch valve

- Control methods: Pinch valves from Magnetbau Schramme are controlled by electromagnetic actuators. This design enables direct or automated control of the flow.

- Automated control: In automated applications, pinch valves are often integrated into process control systems based on real-time data such as pressure and temperature to ensure precise flow control and adjustment.

- Hygienic control: For applications in sensitive areas such as medical technology and the food industry, hygienic control systems are used that enable contactless control of the valve to prevent contamination and maintain hygiene.

Environmental requirements for pinch valves

- Temperature range: Pinch valves must be able to operate in a wide temperature range, typically from -40 °C to +150 °C, without compromising their performance. High operating temperatures can cause the material to overheat and affect the seals, while very low temperatures can make the material brittle.

- Protection classes: Depending on the application environment, pinch valves are equipped with different protection classes (e.g. IP protection classes) to protect them from dust, moisture and other environmental influences and to ensure long-term functionality.

Pinch valves - Questions & Answers

What is the difference between a classic valve and a hose clamp valve?

The main difference between a classic valve and a hose clamp valve lies in the way they work: Classic valves regulate the flow by opening or closing an orifice, while hose clamp valves control the flow by mechanically clamping a flexible hose. Hose clamp valves are particularly suitable for hygiene-critical applications, as the medium does not come into contact with the valve body, whereas classic valves are often used in permanently installed pipework systems. In addition, hose clamp valves offer easier installation and more flexibility in the arrangement within systems.

How does the use of hose clamp valves in a vacuum work?

Hose clamp valves can be used in vacuum applications by precisely controlling the flow of gases or liquids while clamping off the hose to prevent air or contaminants from entering. However, when used in a vacuum, the valves must be designed to overcome external atmospheric pressure while maintaining the integrity of the hose to ensure a secure seal. The selection of appropriate materials and seals is critical to ensure that the valves function reliably under vacuum conditions without failing or leaking.

What are the biggest advantages of pinch valves compared to conventional valves?

No valve parts in contact with the medium: The medium only comes into contact with the hose, which means that no contamination can occur in the pinch valve.

Quick, unrestricted installation: Space-saving design and installation in any position enables simple installation in practice. Furthermore, there is no intervention in the medium when replacing the pinch valve.

Low power requirement: The pinch valve only requires 3 watts of power when switched on.

Durable components: We install high-quality components to provide our customers with the highest quality.

Maximum flexibility: Flow can be in both directions and can be used with 1 or 2 hoses.

In which area are pinch valves most frequently used?

Pinch valves are mainly used in medical technology, especially for infusion and transfusion units, as well as in the food and beverage industry, where they ensure hygienic handling and precise control of the fluid flow. These areas require high standards of hygiene and effective protection against contamination.

What is the difference between a pinch valve and a squeezing valve?

The main difference between a pinch valve and a squeezing valve is the way they work: A pinch valve mechanically pinches a flexible hose to control flow, while a squeezing valve regulates flow through a squeezing motion of an additional elastic hose or hose cuff. Pinch valves allow a clear opening or closing of the flow, while squeezing valves offer the possibility of finer dosing of the flow. Both valve types have their specific advantages and can be used optimally depending on the application and requirements.

Can pinch valves switch and control proportionally?

Pinch valves can both switch and regulate by controlling the flow by mechanically pinching the hose. With proportional technology, they enable finer adjustment of the liquid or gas flow, which is particularly advantageous in applications with precise dosing requirements.

Are pinch valves gas-tight?

Pinch valves can be gas-tight, provided they are installed correctly and the materials used are suitable for the media in question. Proper sealing is ensured by applying the correct pressure to the hose and selecting suitable seals, which minimises the risk of leaks.

Where are pinch valves used?

Here are a few relevant examples: Filling systems, dosing systems, food technology, beverage automation, coffee machines, water treatment, medical technology, analytical technology, chemical process engineering, pharmaceutical process engineering, measurement and control technology.