Rapid development, validation & industrialisation.

Switching solenoids (On/Off solenoids)

Are you looking for a reliable partner for high-quality switching solenoids? Then Magnetbau Schramme is the right place for you! As a specialist in the development and production of customised switching solenoids, we offer you innovative solutions that are perfectly tailored to your requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of switching solenoids

Our performance and expertise. Your success.

Magnetbau Schramme is your expert for product development and series production of switching solenoids. With our many years of experience and comprehensive technical expertise, we develop customised switching solenoids that are optimally tailored to your individual requirements. From the initial idea to the finished series-produced switching solenoid, we support you every step of the way.

Contact us today and let our experts advise you individually.

Please note!

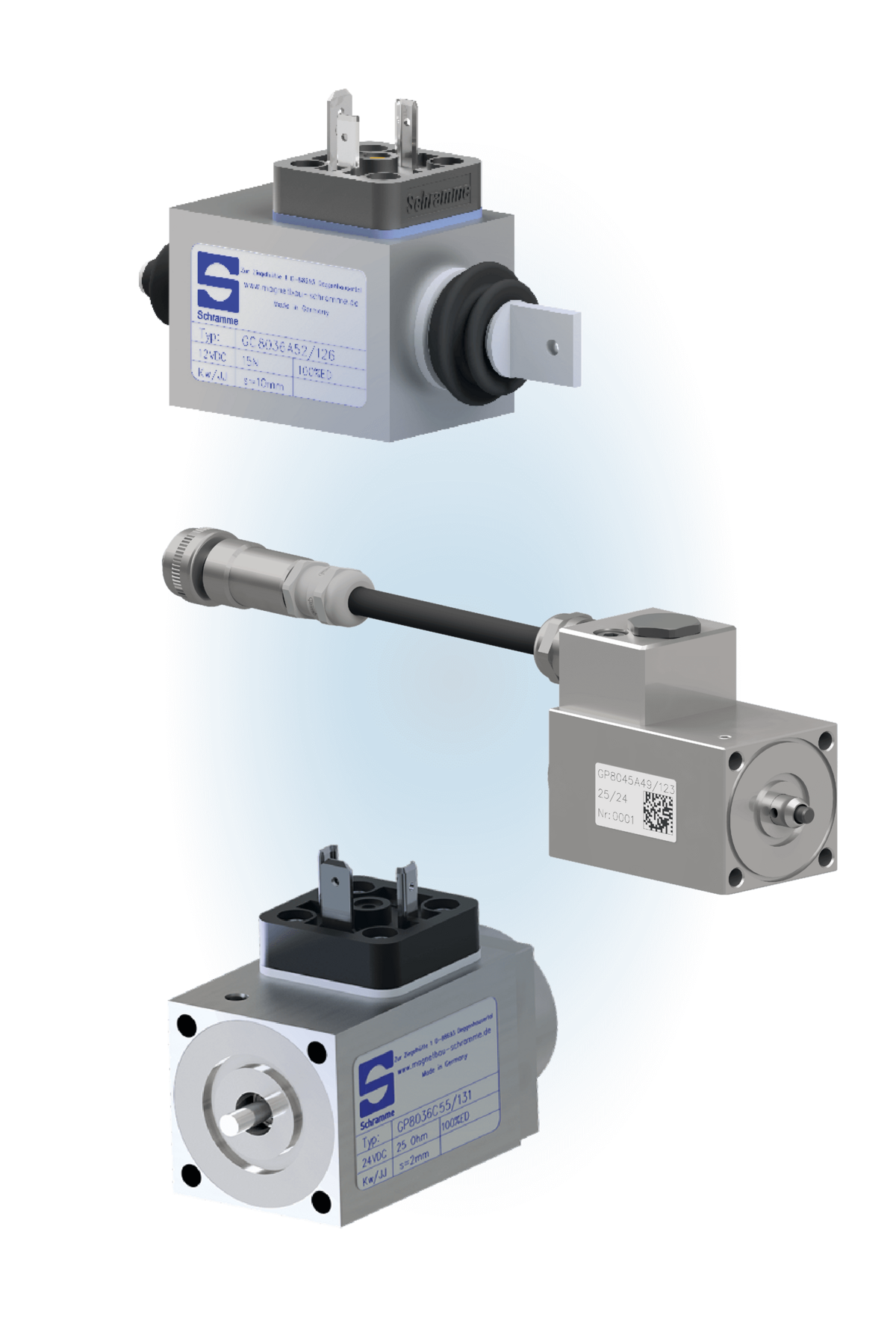

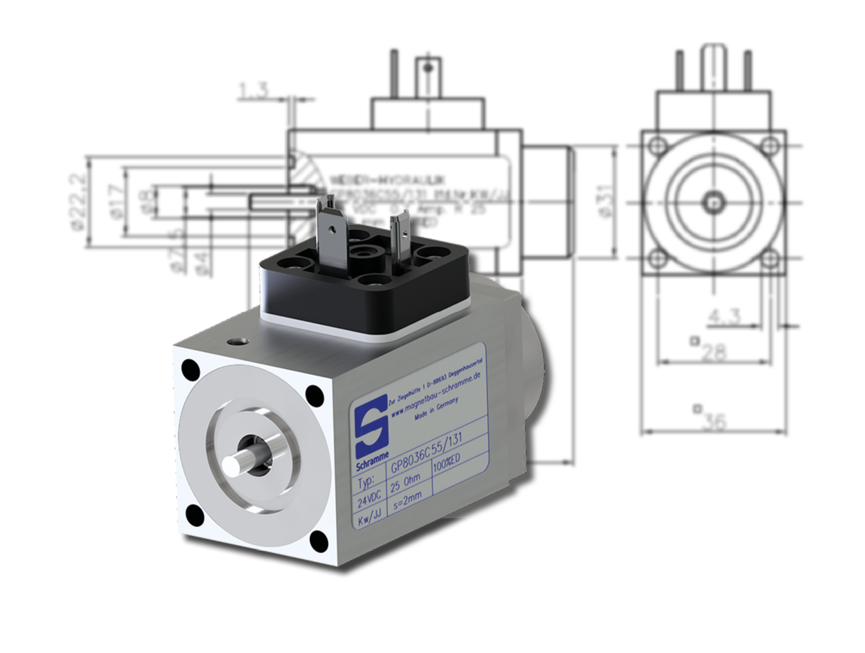

Please note that we do not have any standard products. The following solenoids are merely examples of customer projects that have been realised in series.

Technical data - Switching solenoids

Experience the wealth of different possibilities.

Switching solenoids can be designed for continuous, short-term or periodic operation. In contrast to control solenoids, they are characterised by the fact that they can only switch between two states (on/off), while proportional solenoids enable variable settings and continuous control.

Switching solenoids differ in terms of current, forces and strokes as well as geometric designs; they can be customised based on requirements and can be used in challenging environmental conditions.

Do you have any questions about our technical data or other details that you would like to discuss? Please do not hesitate to contact us.

| Construction size | No limitation, up to a max. construction weight of 15kg. |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Magnetic stroke | up to 20mm |

| Lifting force | up to 1000N |

| Protection class / protection type | up to IP6K9K |

| Electrical connection | Free stranded wires, assembled connectors, integrated (moulded) connectors, etc. |

| Special features | Long service life, fast switching times, AC applications |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised switching and control solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about switching solenoids

How a switching solenoid works

- Switching solenoids are electrical components that generate a magnetic field by applying a voltage and can thus trigger mechanical movements or switching operations.

- Electromagnetism: Switching solenoids utilise electromagnetism. A coil, usually with a ferromagnetic core at its centre, generates a magnetic field when an electrical voltage is applied. This magnetic field attracts a movable armature, which triggers a mechanical movement or a switching process.

- Duty cycle: Switching solenoids can be designed for continuous operation (ED 100%), short-time operation or periodic operation. The duty cycle indicates how long a switching solenoid can remain switched on without overheating.

Designs and types of switching solenoid

- Square switching solenoids: These solenoids have a rectangular cross-section. Due to their compact design, they are well suited for applications where the available space is limited. They are easy to mount in the respective customer application and often offer high efficiency.

- Round switching solenoids: These solenoids have a cylindrical cross-section and are generally more cost-effective to manufacture, as moulded housing components can be used. The round shape reduces the amount of material used.

Switching solenoid performance parameters

- Voltage and current: Switching solenoids typically work with direct current (DC) or alternating current (AC). The operating voltage and operating current vary depending on the application.

- Force: The forces of a switching solenoid depend on the current, the number of turns in the coil and the design of the solenoid system. Usual values can range from a few Newtons to several hundred Newtons.

- Stroke: The stroke is the distance travelled by the armature. Typical stroke lengths range from a few tenths of a millimetre to several centimetres.

Structure of the switching solenoid

- Housing: The housing protects the internal components of the switching solenoid and is also made of ferromagnetic material. An additional housing made of steel, aluminium or plastic can be attached, depending on the application and the ambient conditions.

- Coil: The coil usually consists of a wire winding with a magnetisable core in the centre. The wire used for the coil is usually made of a highly conductive material such as copper . The number of turns in the coil, the current strength and the shape of the coil influence the properties of the magnetic field generated

- Armature: The armature is the moving component that strives for the ideal state of the iron circuit when the switching solenoid is energised, i.e. it minimises the working air gap and thus moves towards the iron core.

- Iron core: Switching solenoids usually use ferromagnetic materials such as soft iron for the core in order to maximise the magnetic field strength in the area of the working air gap.

- Electrical connection: The electrical connection of switching solenoids is crucial for their reliable operation and safe integration into an overall system. Depending on the application and design, there are different types of electrical connections that are used for switching solenoids.

Switching solenoid applications

- Automotive industry: In locking systems, engine management, transmission controls, chassis systems, brakes, steering, etc.

- Medical technology: In medical pumps, ventilators, dialysis systems, laboratory equipment, etc.

- Industrial automation: In valve controls, sorting systems, conveyor technology, robot arms, safety systems, etc.

- Household appliances: In washing machines, dishwashers, coffee machines, etc.

- Safety technology: In door locking systems, fire protection systems, access systems, automatic doors and gates, etc.

Control and regulation of switching solenoids

- Control: Switching solenoids are often controlled by electronic driver circuits that allow them to be switched on and off in quick succession. These circuits can use PWM (pulse width modulation) to precisely control the current.

- Sensor integration: In some applications, switching solenoids are combined with sensors that monitor the position of the armature to enable precise movement and feedback.

Environmental requirements for switching solenoids

- Temperature range: Switching solenoids are often designed to operate in a wide temperature range, typically from -40°C to +150°C or even higher.

- Protection classes: Depending on the application, switching solenoids can be realised with different protection classes (e.g. IP protection classes) to protect them from dust, water and other environmental influences.

Shifting solenoid (On/Off solenoids)- Questions & Answers

What is a switching solenoid?

A switching solenoid is an electromagnetic component that triggers mechanical movements with the help of a generated magnetic field through the supply of current in order to control switching processes.

What is the difference between a switching solenoid and a proportional solenoid?

The main difference between a switching solenoid and a proportional solenoid is their function. Switching solenoids only switch between two states (on/off), while proportional solenoids enable variable settings and continuous control.

How much force can switching solenoids generate?

Switching solenoids can generate different forces depending on their design and size. The magnetic forces typically vary from a few newtons (N) to several hundred newtons (N).

How does a switching solenoid work?

A switching solenoid works with the help of electromagnetism. When an electrical voltage is applied, current flows through a coil, in the centre of which there is usually a ferromagnetic iron core. The current generates a magnetic field. This magnetic field ensures that a movable armature moves towards the iron core. This armature is mechanically connected to a switching element. The attraction of the armature triggers a mechanical movement or switching operation that can be used to open or close a switch, valve or locking system. When the electrical voltage is removed, the magnetic field also drops and the armature returns to its original position by means of a spring or other return mechanism.

What distinguishes a switching solenoid from other electromagnetic products?

The switching solenoid is a specialised electromagnet that is used for the direct control of mechanical switching processes. The switching solenoid, also often referred to as a relay or actuator, is primarily used to trigger mechanical movements or to close or open electrical contacts.

How many switching operations can a switching solenoid perform?

The number of cycles depends on various factors, including the design, load, operating conditions and maintenance (mechanical life, electrical life). Typically, the service life of a switching solenoid ranges from hundreds of thousands to several million cycles.