Rapid development, validation & industrialisation.

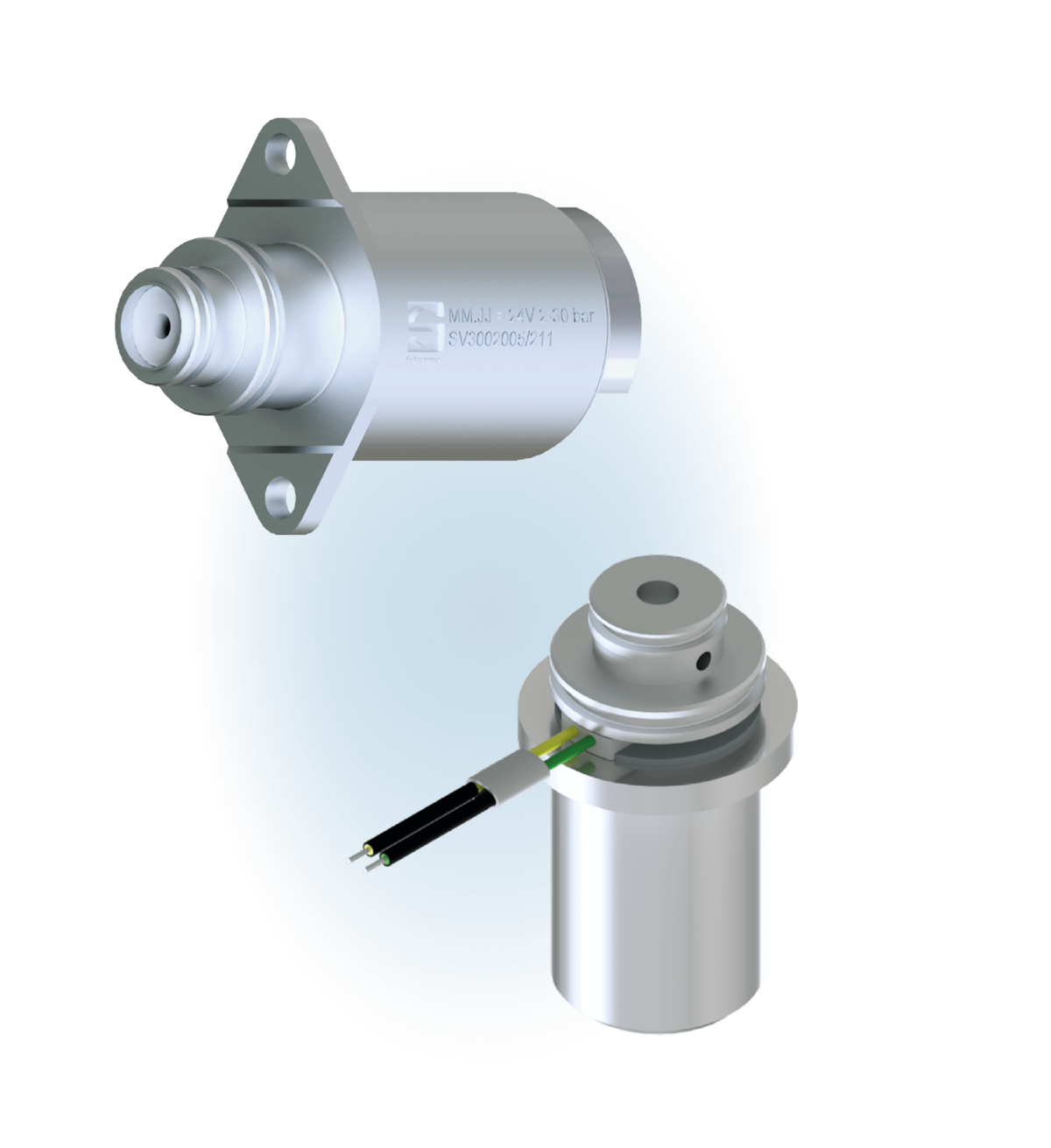

Spool valves

Are you looking for a reliable partner for high-quality cartridge valves? You've come to the right place at Magnetbau Schramme! As a specialist in the development and manufacture of customised spool valves, we offer innovative and precise solutions that are precisely tailored to your specific requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of spool valves

Our performance and expertise. Your success.

Magnetbau Schramme is your experienced partner for the development and series production of cartridge valves. With our extensive technical expertise and many years of experience, we offer you customised solutions that are precisely tailored to your specific requirements. From concept development to series production, we will guide you through the entire process and ensure that every phase of your project is realised smoothly.

Contact us today for personalised advice from our experts.

Please note!

Please note that we do not have any standard products. The following cartridge valves are merely examples of customer projects realised in series.

Technical data - Spool valves

Experience plenty of different possibilities.

A cartridge valve is a mechanical control valve used to regulate the flow of liquids or gases. It works by moving a "piston" within the valve body. Depending on the position of the spool, the flow is fully or partially released or blocked. These valves are particularly suitable for applications with large diameters and high pressures, as they have low flow resistance.

Do you have any questions about our technical data or other details that you would like to discuss? Please do not hesitate to contact us.

| Construction size | No limitation, up to a max. construction weight of 15kg. |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Magnetic stroke | up to 8mm |

| Force | up to 100N |

| Protection class / protection type | up to IP6K9K |

| Electrical connection | Free stranded wires, surface-mounted connectors, integrated (moulded) connectors, etc. |

| Special features | Friction-optimised (lowest hysteresis), definable hydraulic characteristic curve |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised solenoid valves and further solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about spool valves

How a spool valve works

Electromagnetic spool valves (also known as solenoid valves) use an electromagnet to control the spool (the moving part of the valve) and thus open or close the flow of a medium.

- The movement of the solenoid armature moves the spool into the position that either releases or blocks the flow. With a normally closed (de-energised closed) valve, the solenoid armature moves the gate to the open position and allows the flow; with a normally open (de-energised open) valve, the flow is reduced or interrupted by the magnetic field.

- When the electrical voltage is switched off, the magnetic field disappears and the armature returns to its original position. A return spring or the pressure of the medium pushes the spool back to its original position, which closes or opens the flow accordingly.

- Electromagnetic spool valves are therefore ideal for applications that need to be controlled precisely, quickly and often remotely, such as in automation and control systems, in industrial machines or even in household systems. Electromagnetic spool valves are often used as so-called cartdrige valves in stationary or mobile hydraulics.

Designs and types of spool valve

- Square spool valves: These spool valves have a rectangular housing profile. Thanks to their compact design, they are particularly suitable for applications with limited installation space. They can be easily integrated into different systems and offer reliable function for the safe flow of media, depending on the design and actuation mechanism.

- Round spool valves: These valves have a cylindrical body, which often makes them more cost-efficient, as they can be manufactured from simpler or tool-less components.

Performance parameters Gate valve

- Tightness: For gate valves, tightness describes the ability of the gate valve to prevent leakage when closed. In contrast to poppet valves, which rely on the precision of the sealing surface, gate valves usually offer a defined and acceptable leakage rate due to their design.

- Flow rate: The flow rate (in L/min) of a spool valve is determined by the design and the valve diameter. Spool valves offer an almost unrestricted flow rate, as the spool valve usually opens up the entire flow path, which makes them particularly suitable for large pipe cross-sections and high volume flows.

- Pressure loss: Spool valves minimise pressure loss when open, as the flow path remains virtually unobstructed. This reduces energy losses and increases the efficiency of the overall system, especially with large diameters.

- Temperature range: Spool valves are suitable for high temperatures, depending on the material of the body and the seals. They are often used in systems with high temperature requirements, e.g. in the petrochemical industry or power generation.

- Actuating force: The actuating force (in Newtons) of spool valves is highly dependent on the requirements and the valve design. Pressure-balanced systems are designed so that the gate valve does not have to move against the pressure of the medium and can therefore be actuated independently of the pressure.

- Materials: The choice of material for gate valves is decisive for their resistance to corrosive media and high temperatures. Frequently used materials are steels or other ferrous materials, depending on the area of application, e.g. in the chemical industry or in power plant construction, where durability and corrosion resistance are essential.

Structure of the gate valve

- Body: The body of the spool valve forms the outer structure and is usually made of resistant materials. It houses all other components and ensures the mechanical stability of the valve.

- Valve body: The valve body forms the housing of the valve and contains the inlet and outlet openings through which the medium (e.g. liquid or gas) flows. Inside the valve body is the spool or piston, which moves to regulate the flow.

- Spool: The spool is the moving part that moves orthogonally to the direction of flow to block or unblock the flow. Its shape, accuracy and surface are decisive for the tightness, control quality and flow resistance of the valve.

Applications spool valve

- Industrial applications: Spool valves are used for the precise control of liquids and gases. They can be found in heating systems, irrigation systems, industrial process controls and many automated systems where the control of the flow of media is required.

- Vehicle construction: Spool valves can be used in fuel lines to regulate the flow of fuel and keep the pressure constant. In air conditioning and heating systems, they regulate the flow of refrigerant and control the heating or cooling in the vehicle.

- Building technology: Spool valves: They are used in water treatment systems such as water filters, softening systems and water purification systems to control the flow of water in certain phases of filtration.

- Aerospace: Electromagnetic spool valves control hydraulic fluids in aeroplanes, e.g. for landing gear, flaps and other moving parts. They are also used to regulate the fuel flow and ensure that the various systems in the aircraft are supplied safely.

- Food and beverage industry: In plants that process liquids such as milk, juice or water, hygienic spool valves are used to control the flow and ensure high standards of hygiene.

Control and regulation of spool valves

- Actuation: Electromagnetic spool valves are mainly controlled by electrical signals that activate an electromagnet (coil) and thus move the gate valve. Control and regulation is typically performed by various electronic components and control systems, which can vary depending on the application and requirements.

- Regulation: In proportionally controlled solenoid spool valves, the solenoid can continuously regulate the position of the gate, allowing precise control of the flow. A varying electrical signal (e.g. 0-10 V or 4-20 mA) controls the solenoid coil proportionally, which means that the spool valve can be moved to intermediate positions. Advantage: The volume flow can be controlled as required, which is ideal for applications where precise dosing or control is required.

Environmental requirements spool valve

- Temperature range: Spool valves must function reliably in a wide temperature range from -40 °C to +150 °C without losing their performance. High temperatures can affect the seals, while very low temperatures can make the materials brittle and limit the valve's manoeuvrability. The materials used and the construction of the spool valve must therefore be designed for these temperature conditions in order to ensure long-lasting and safe operation.

- Protection classes: Depending on the area of application, spool valves are equipped with protection classes such as IP classes, which protect the valve from dust, moisture and other environmental influences. These protective measures are particularly important to ensure the longevity and reliability of the valve under harsh operating conditions.

Spool valves - Questions & Answers

What is the difference between a poppet valve and a slide valve?

The main difference between a gate valve and a globe valve lies in the direction of movement of the shut-off body. In spool valves, a spool moves perpendicular to the direction of flow to fully open or close the flow, while poppet valves use a valve disc that moves axially towards a seat to regulate or shut off the flow. Spool valves are better suited for very large volume flows, while poppet valves primarily enable very low leakage rates.

What design variants of electromagnetic spool valves are available?

There are different design variants of electromagnetic spool valves, which differ in terms of their construction, mode of operation and application. A common variant is normally closed (NC) and normally open (NO) valves; NC valves are closed when not energised and open when the solenoid is energised, while NO valves are open when not energised and close when energised. There are also bistable valves that can hold their position even without a power supply, which saves energy. Proportional valves allow infinitely variable flow control, while pulse-operated valves are controlled by short current pulses. There are also multiport valves, which have several connections and can control the flow in different directions. In addition, special media valves are manufactured for different liquids or gases, as well as hygienic valves, which are designed for use in food and pharmaceutical technology to ensure the highest standards of cleanliness.

How reliable are spool valves under extreme operating conditions, such as high pressures or aggressive media?

Spool valves are very reliable under extreme operating conditions such as high pressures or aggressive media, especially if they are made of resistant materials such as stainless steel or special alloys. They offer robust seals that prevent leaks even under high pressure or abrasive media.

What types of electromagnetic actuators are available for gate valves?

There are various electromagnetic actuators for gate valves, including linear solenoids, which move the gate in a linear fashion, and rotary solenoids, which create a rotating motion. Proportional solenoids allow finer control of the valve position, which is important for more precise flow regulation. These actuators are often used in automated systems to ensure fast and precise movements.