ISO 9001 & IATF 16949 certified as developer & producer of electromagnets.

Commercial vehicles

Discover how our innovative electromagnet solutions and pioneering technologies are shaping the future of commercial vehicles.

Use of electromagnets

Reliability and power: electromagnets optimise technology in commercial vehicles

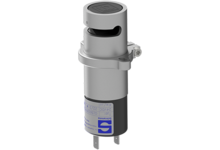

Solenoids, proportional solenoids and poppet valves from Magnetbau Schramme are designed for the demanding requirements of on- and off-highway commercial vehicles and pioneering hydrogen applications in the automotive sector.

Application examples for solenoids in the commercial vehicle sector

- Seat valve for steering unit in commercial vehicles

- Proportional solenoid for high-pressure control unit of an H2 supply system

- Proportional solenoid for controlling a retarder in a commercial vehicle

- And many more

Precision and reliability in demanding applications

Electromagnets enable precise control in brake systems and door locks, while proportional solenoids enable hydraulic control in construction and agricultural machinery. Seat valves ensure reliable sealing and precise pressure control, even in high-pressure hydrogen systems. Magnetbau Schramme fulfils the strict requirements of IATF 16949 and thus guarantees the highest quality and reliability in all safety-critical applications - from hydraulic solutions to modern hydrogen drives, even under extreme conditions.

Your advantages with Schramme

Development and production of electromagnets for commercial vehicles

Magnetbau Schramme is your experienced partner for the development and series production of high-quality electromagnets for commercial vehicles in the automotive sector. With decades of expertise, we offer customised solutions that meet the highest demands for precision, reliability and automotive standards.

From the initial concept phase through to series production, we provide you with comprehensive support and, thanks to flexible manufacturing processes, we can efficiently realise individual requirements. You can rely on "Made in Germany" quality for your innovative applications in commercial vehicles, whether for conventional drives or modern hydrogen technologies.

More than 50 years of experience in the development & series production of electromagnets.

CNC, welding, soldering, injection moulding assembly (ESD / clean room) and much more.

Alexander Grischin

Sales Manager

Valve solenoid application example

Steering axle for commercial vehicles

A valve solenoid in the valve block of a trailer steering axle controls precise hydraulic valves that regulate the flow of hydraulic oil.

It ensures optimum steering assistance by adjusting the actuating force of the steering depending on the speed. This results, for example, in smooth steering at low speeds and steering stability at higher vehicle speeds. In addition, the valve solenoid supports safety and assistance systems, making steering more efficient, precise and fail-safe.

Technical requirements

How Magnetbau Schramme solves the technical requirements

Electromagnetic drives in on- and off-highway commercial vehicles must guarantee high performance, reliability and robustness under extreme conditions. The requirements include high holding and switching forces, fast response times and a long service life with minimal maintenance.

They must be resistant to vibrations, temperature and humidity fluctuations. In addition, they are often optimised for precise control of hydraulic systems, brake and door mechanisms. Compliance with strict standards such as IATF 16949 ensures quality and durability for demanding applications.

- Seat valve for steering unit in commercial vehicles

- Proportional solenoid for high-pressure control unit of an H2 supply system

- Proportional solenoid for controlling a retarder in a commercial vehicle

- And many more

More information about electromagnets in the commercial vehicle sector

1. Solenoid types

In commercial vehicles, solenoids, linear solenoids, proportional solenoids, solenoid valves and seat valves are used in particular. Solenoids control functions such as door locks and brake systems. Linear solenoids and proportional solenoids precisely control hydraulic systems. Solenoid valves and poppet valves ensure reliable control and pressure regulation in hydraulic and pneumatic systems, which are essential in commercial vehicles.

2 Industry-specific technical requirements

In the field of electromagnets for commercial vehicles, the components must meet the highest standards of precision, reliability and durability. Compliance with IATF 16949, which specifies strict quality and manufacturing standards for the automotive industry, is particularly important, as is ensuring high production repeatability. Electromagnets must be able to work reliably under extreme vibrations, temperatures and humidity conditions. They are also designed for fast response times, strong holding power and low maintenance requirements to maximise the efficiency of control and drive systems in on- and off-highway applications.

Robustness and a long service life are crucial for reliable use in commercial vehicles.

3. Special features

In the commercial vehicle industry, electromagnets require particular robustness against extreme environmental conditions such as vibrations, dust, moisture and temperatures. They must also fulfil the highest vehicle safety requirements, particularly with regard to EMC (electromagnetic compatibility) and long-term reliability under load.

Electromagnets for commercial vehicles - Questions & Answers

How does Magnetbau Schramme guarantee the quality and reliability of its electromagnetic drives for commercial vehicles?

Magnetbau Schramme ensures that all electromagnetic drives undergo rigorous testing and quality control in accordance with international standards such as IATF 16949. Our products offer maximum precision, durability and resistance, even under extreme operating conditions. Our flexible manufacturing processes enable customised solutions for specific requirements in commercial vehicles.

What does on- and off-highway mean in the automotive commercial vehicle sector?

In the commercial vehicle sector, on-highway refers to vehicles that are designed for use on public roads, such as lorries, buses and delivery vans. Off-highway vehicles, on the other hand, are intended for use off public roads, for example in agriculture, construction or the mining industry. These vehicles are specially designed for demanding, unpaved or difficult terrain and require robust and specialised technology.

What applications are there for electromagnets in commercial vehicles in the field of hydrogen as a future technology?

Electromagnets play a key role in hydrogen technology for commercial vehicles, particularly in the control of hydrogen valves, safety valves and cylinder controls. They enable precise regulation of the hydrogen flow in fuel cells, refuelling and distribution systems. Solenoids also ensure the safe shutdown of hydrogen systems in the event of leaks or overpressure, which is essential for the safety and efficiency of hydrogen vehicles.

What does a proportional solenoid do when controlling a retarder?

A proportional solenoid controls the retarder by precisely regulating the hydraulic valves that adjust the brake pressure in the retarder. The continuous, fine control of the solenoid adjusts the braking force in proportion to the desired deceleration, which enables a smooth and controlled braking effect. This increases safety and efficiency when braking, especially in demanding driving situations.

What are the legal requirements and standards for electromagnetic drives in commercial vehicles?

Several standards and requirements apply to electromagnetic drives in commercial vehicles. Important specifications include IATF 16949 for quality management in the automotive industry and the EMC Directive (2014/30/EU) on electromagnetic compatibility. In addition, electromagnetic drives often have to fulfil the requirements of IEC 60079 for explosive atmospheres and ISO 13849-1 for functional safety in order to ensure safety and reliability in vehicle applications.