Rapid development, validation & industrialisation.

Proportional solenoids

Are you looking for a reliable partner for high-quality proportional solenoids? Magnetbau Schramme is the right place for you! As a specialist in development and production of customised proportional solenoids, we offer innovative and precise solutions that are optimally tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of proportional solenoids

Our performance and expertise. Your success.

Magnetbau Schramme is your competent partner for the development and series production of proportional solenoids. With our comprehensive technical expertise and many years of experience, we realise customised solutions that are perfectly tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure seamless implementation at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

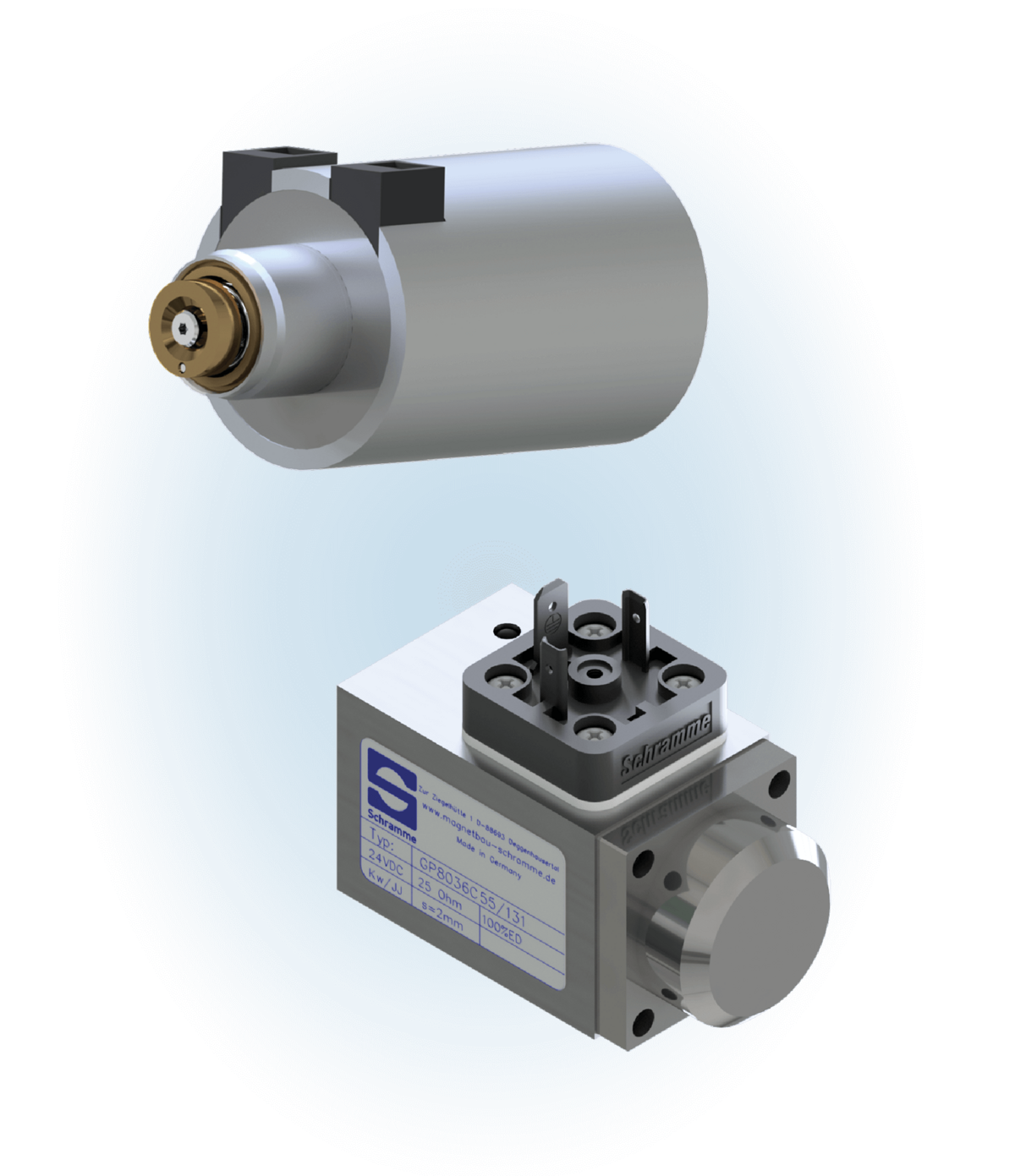

Please note that we do not have any standard products. The following proportional solenoids are merely examples of customer projects realised in series production.

Technical data - Proportional solenoid

Experience the wealth of different possibilities.

Proportional solenoids are designed for applications that require continuous and precise control of forces and movements. Compared to switching solenoids, which only switch between two states (on/off), proportional solenoids enable variable control in which the output force or stroke is regulated proportionally to the applied current.

They offer a high degree of flexibility in terms of current, forces and stroke lengths and can be customised according to specific customer requirements. Proportional solenoids are ideal for use in demanding environments that require high precision and reliability.

Do you have any questions about our technical data or other details you would like to discuss? Please do not hesitate to contact us.

| Construction size | No limitation, up to a max. construction weight of 15kg. |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Magnetic stroke | up to 20mm |

| Force | up to 200N |

| Protection class / protection type | up to IP6K9K |

| Electrical connection | Free stranded wires, assembled connctors, integrated (moulded) connectors, etc. |

| Special features | Friction-optimised (minimum hysteresis), also for pneumatic applications, definable force-stroke characteristic |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised switching and control solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about proportional solenoids

How proportional solenoids work

Proportional solenoids are electromagnetic components for the continiuous control of forces and movements. Their mode of operation is based on the proportional relationship between the applied current and the magnetic force. Compared to switching solenoids, which only switch on/off, proportional solenoids enable fine and linear regulation or control, in which the force or stroke is varied depending on the current supply.

- Power supply: When an electric current is passed through the solenoid coil, a magnetic field is created. This magnetic field generates an attractive force on a moving armature inside the solenoid.

- Proportionality: The decisive aspect of proportional solenoids is that the strength of the magnetic field, and therefore the attractive force on the armature, is directly proportional to the applied current. This means that the more current flows through the coil, the stronger the force generated and the further the armature moves.

- Movement and force control: This proportionality means that the armature of the solenoid can not only switch between two positions (as with a switching solenoid), but can also move continuously. This enables precise control of movements or forces, which is useful in applications such as valve controls or damping systems.

- Restoring force: A restoring force often acts on the armature, for example through a spring. This force is also balanced with the magnetic force so that the armature can be brought into an exact position that corresponds to the applied current.

- Continuous control: By adjusting the current, the solenoid can react in real time and dynamically generate different forces or movements. This continuous control is particularly advantageous in systems that require high precision.

Designs and types of proportional solenoids

- Square proportional solenoids: These solenoids have a rectangular cross-section. Due to their compact design, they are well suited for applications where the available space is limited. They can be easily integrated into the respective customer application and often offer high precision in proportional control.

- Round proportional solenoids: These solenoids have a cylindrical cross-section and are usually more cost-efficient, as they can be manufactured with moulded housing components. The round design ensures a uniform distribution of the magnetic field, which can have a positive effect on the function of the reversing solenoid.

Performance parameters Proportional solenoids

- Rated current: The current at which the proportional solenoid delivers its specified power. Typical range: From a few milliamperes (for small applications) to several amperes (for industrial applications).

- Nominal voltage: The operating voltage at which the proportional solenoid works. It can vary depending on the type of solenoid and application. Typical ranges: 12V, 24V or 48V for industrial applications.

- Stroke : The linear displacement of the magnetic armature, which is directly dependent on the input signal. The stroke is an important measure for motion control. Typical range: From a few millimetres to several centimetres, depending on the application.

- Force-displacement characteristic: The relationship between the applied electrical power (current or voltage) and the resulting mechanical force over the entire stroke. Proportional solenoids are characterised by a uniform, linear or non-linear force development. This characteristic curve describes the accuracy and efficiency of the movement.

- Holding time/holding force: The force that the solenoid can maintain in the active state over a longer period of time without the power decreasing. This is particularly important for applications in which a position must be held stable over a longer period of time. This holding force is influenced by the magnetic field strength and the coil structure.

- Duty cycle: The maximum period during which the proportional solenoid can be operated under load without overheating or overloading. This is specified as a percentage value (ED %). Typical range: 100% ED for continuous duty solenoids, lower values for intermittent applications.

- Magnetic force: The maximum force that the solenoid can generate at maximum electrical power consumption. This is an important parameter for applications where high forces are required. Typical range: From a few newtons to several kilonewtons, depending on the size and design.

- Inductance: The inductance of the solenoid coil influences the dynamics and speed of the control. Higher inductivities lead to slower response times. Typical range: Millihenry to Henry, depending on the design.

Proportional solenoid design

- Housing: The housing protects the internal components and is often made of ferromagnetic material to optimise magnetic field conduction. Depending on the application, additional housings made of steel, aluminium or plastic can be fitted. For precise control, the housing is often also designed for thermal properties.

- Coil: The coil consists of conductive wire, usually copper, which is often wound on a bobbin. The coil arrangement enables a magnetic field that increases in proportion to the current for precise force or movement control. The number of windings and the geometry of the coil influence the force development.

- Armature: The armature moves in proportion to the current supply and strives to minimise the working air gap. In contrast to switching solenoids, the movement of the armature is uniform, which requires a precise design for exact force development.

- Iron core: Made of soft iron, the core concentrates the usable magnetic field strength. The design of the iron core is decisive for the uniform movement of the armature and the proportional control characteristics. Working air gap: The working air gap is decisive for the stroke and force and therefore also has an influence on the control accuracy and uniform control of the armature.

Proportional solenoid applications

- Hydraulics and pneumatics: Proportional solenoids control valves to regulate the flow of liquids or gases. They enable precise pressure and flow control in hydraulic and pneumatic systems.

- Automotive industry: In automatic transmissions, proportional solenoids control the transmission oil flows for smooth gear changes. They also regulate the fuel quantity in injection systems and optimise consumption and emissions.

- Medical technology: In medical devices such as ventilators and infusion pumps, proportional solenoids precisely dose liquids and gases and ensure safety and efficiency.

- Industrial automation: Proportional solenoids control robots and actuators in manufacturing processes for precise movements. They are used in gripper systems and conveyor systems where stepless movements are required.

- Shipbuilding and aviation: Proportional solenoids control hydraulic systems that move rudder flaps, landing flaps and landing gear. Precision is crucial for safety here.

- Agricultural and construction machinery: In construction machinery and cranes, proportional solenoids control hydraulic systems for attachments and booms to move heavy loads with precision.

- Renewable energies: Proportional solenoids control mechanical and hydraulic systems in wind turbines and solar plants, for example to adjust rotor blades or solar panels.

Control and regulation Proportional solenoid

- Control: Proportional solenoids are controlled by special electronic control units that allow the current to be regulated continuously. Here, pulse width modulation (PWM) or analogue signal control is often used to generate the magnetic field in proportion to the current supply and thus generate precise movements.

- Sensor integration: In many applications, proportional solenoids are equipped with sensors that monitor the exact position of the armature. This feedback allows precise control of the movement and ensures accurate control of the system.

Environmental requirements Proportional solenoid

- Temperature range: Proportional solenoids are designed for use in a wide temperature range, often from -40°C to +150°C or more, to ensure precise and reliable operation even under extreme conditions.

- Protection classes: Depending on the application environment, proportional solenoids are equipped with different protection classes (e.g. IP protection classes) to protect them from dust, moisture and other environmental influences and to ensure long-term functionality.

Proportional solenoids - Questions & Answers

What is the difference between a switching solenoid and a proportional solenoid?

The main difference between a switching solenoid and a proportional solenoid is their function. Switching solenoids only switch between two states (on/off), while proportional solenoids enable variable settings and continuous control.

How does a proportional solenoid work?

A proportional solenoid works by generating a magnetic field that controls the position of a moving armature. It receives an electrical signal that is proportional to the desired armature position or armature force. Depending on the intensity of the signal, the armature usually moves a slide or piston of a valve in such a way that a volume flow or pressure is regulated. This precise control makes it possible, for example, to finely adjust the hydraulic power, allowing the system to work efficiently and react quickly.

How does the assembly and integration of proportional solenoids into an overall system work?

Proportional solenoids are usually installed in a complete system by attaching the solenoid to a proportional valve that is integrated into the hydraulic or pneumatic line. The electrical connection to the control system is also established. When integrated into the overall system, the proportional solenoids are incorporated into a network of sensors and controllers to ensure smooth communication and control, often via industrial protocols such as CANopen or EtherCAT. After installation, the system is calibrated to ensure that the proportional solenoids respond accurately to the desired signals and precisely set the required flow or pressure values.

Where are proportional solenoids integrated in the Industry 4.0 environment?

In an Industry 4.0 environment, proportional solenoids are often integrated into automated manufacturing and assembly systems to enable precise control of hydraulic and pneumatic applications. They are part of networked systems in which sensors, actuators and controllers communicate in real time to ensure optimal operating conditions and improved efficiency. They also enable the implementation of predictive maintenance by collecting and analysing continuous data on machine performance and condition to predict maintenance needs.

How is a proportional solenoid controlled?

A proportional solenoid is controlled by an analogue electrical signal that activates the solenoid and controls the opening of the valve in proportion to the desired flow rate or pressure. In many modern applications, control is performed by electronic control units that enable precise regulation, often supported by feedback systems.

What does a proportional solenoid do in hydraulics?

A proportional solenoid in hydraulics controls the flow or pressure in a hydraulic system by regulating the position of a spool or piston in a proportional valve. It receives an analogue electrical signal that is proportional to the desired control variable and generates a magnetic field that triggers the mechanical movement of the valve. In this way, the proportional solenoid enables precise and infinitely variable control of the hydraulic power, which is crucial for the efficiency and responsiveness of hydraulic applications.