ISO 9001 & IATF 16949 certified as developer & producer of electromagnets.

Services

From the initial idea to series production - Schramme offers comprehensive services in development, industrialisation and production.

With state-of-the-art technology and decades of experience, we implement your individual requirements reliably and to the highest quality.

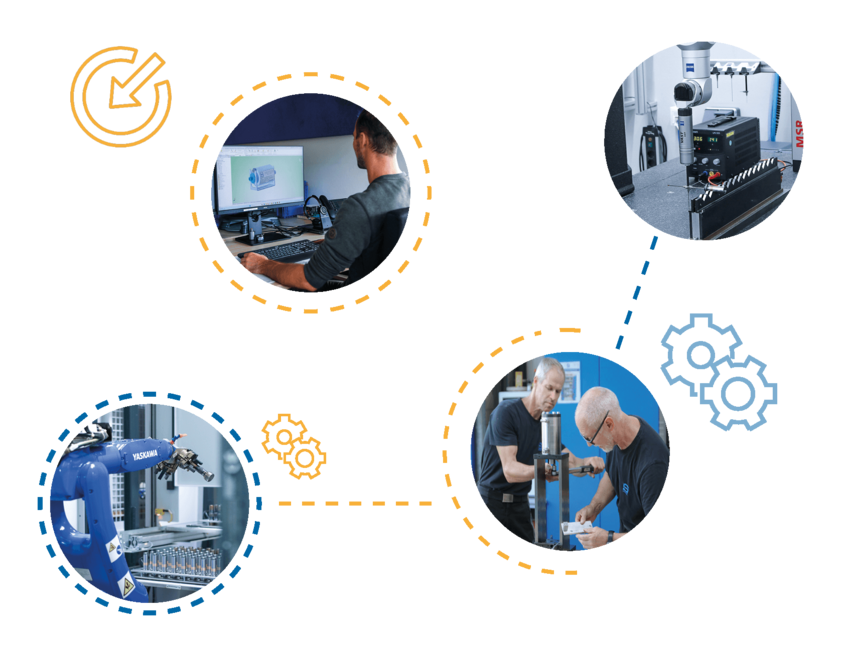

Step 1 - Development

Customised development of electromagnetic drive solutions.

Our engineers develop customised electromagnets according to your technical specifications:

- Analysing and creating the customer's technical specifications (requirements specification) for a clear project definition.

- Concept development, design and simulation using the latest CAD and simulation tools.

- Sample and prototype construction / pre-series for initial functional tests and integration into the customer's overall system.

- Qualification and functional testing (service life tests, environmental simulations, end-of-line).

- Extended development services such as feasibility analyses, thermal calculations and advice on integrating products into complex systems.

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised switching and control solenoids.

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

Step 2 - Industrialisation

Industrialisation of electromagnetic drive solutions.

Our development and industrial engineering team brings your magnet efficiently into series production:

- Selection of production technologies (tools, equipment, etc.) suitable for the number of units.

- Optimisation of the product design (design for manufacturing) for efficient production and assembly.

- Definition of the test strategy based on your quality requirements, ranging from component testing to end-of-line inspections.

- Definition and integration of reliable supply chain partners and efficient logistics concept for smooth supply.

- Processes and products fulfil the highest standards according to ISO 9001 and IATF 16949 for stability, reliability and lasting customer satisfaction.

Your advantages with Magnetbau Schramme

Development and production of electromagnets

Magnetbau Schramme is your reliable partner for the development and series production of high-quality electromagnetic drive solutions for many different applications. With decades of experience, we offer customised solutions that meet the highest precision, reliability and safety standards.

Our expertise extends from the initial idea through to series production, and our flexible production processes ensure that individual requirements can be implemented quickly. Place your trust in quality "Made in Germany" for your innovative applications.

More than 50 years of experience in the development & series production of electromagnets.

CNC, welding, soldering, injection moulding assembly (ESD / clean room) and much more.

Marco Kiene

Management | CSO

Step 3 - Series production

Production of electromagnetic drive solutions.

Short throughput times with the help of hard-working employees and fully automated machines:

- CNC turning and milling technology for maximum precision and surface quality.

- Innovative welding and soldering processes, customised to the material and application, for robust and reliable connections.

- Production of complex plastic components using in-house injection moulding.

- Production of precise and durable solenoid coils / copper coils.

- Final assembly of all components into a functional electromagnet (ESD, clean room).

- Advanced measuring methods for seamless control during and after production.

- Optimisation of processes using lean methods such as VSM, Kanban, CIP, etc.