Solenoid valves

Solenoid valves are individually developed by Magnetbau Schramme according to customer requirements and then manufactured in series. You can rely on our many years of experience and expertise to successfully implement your project.

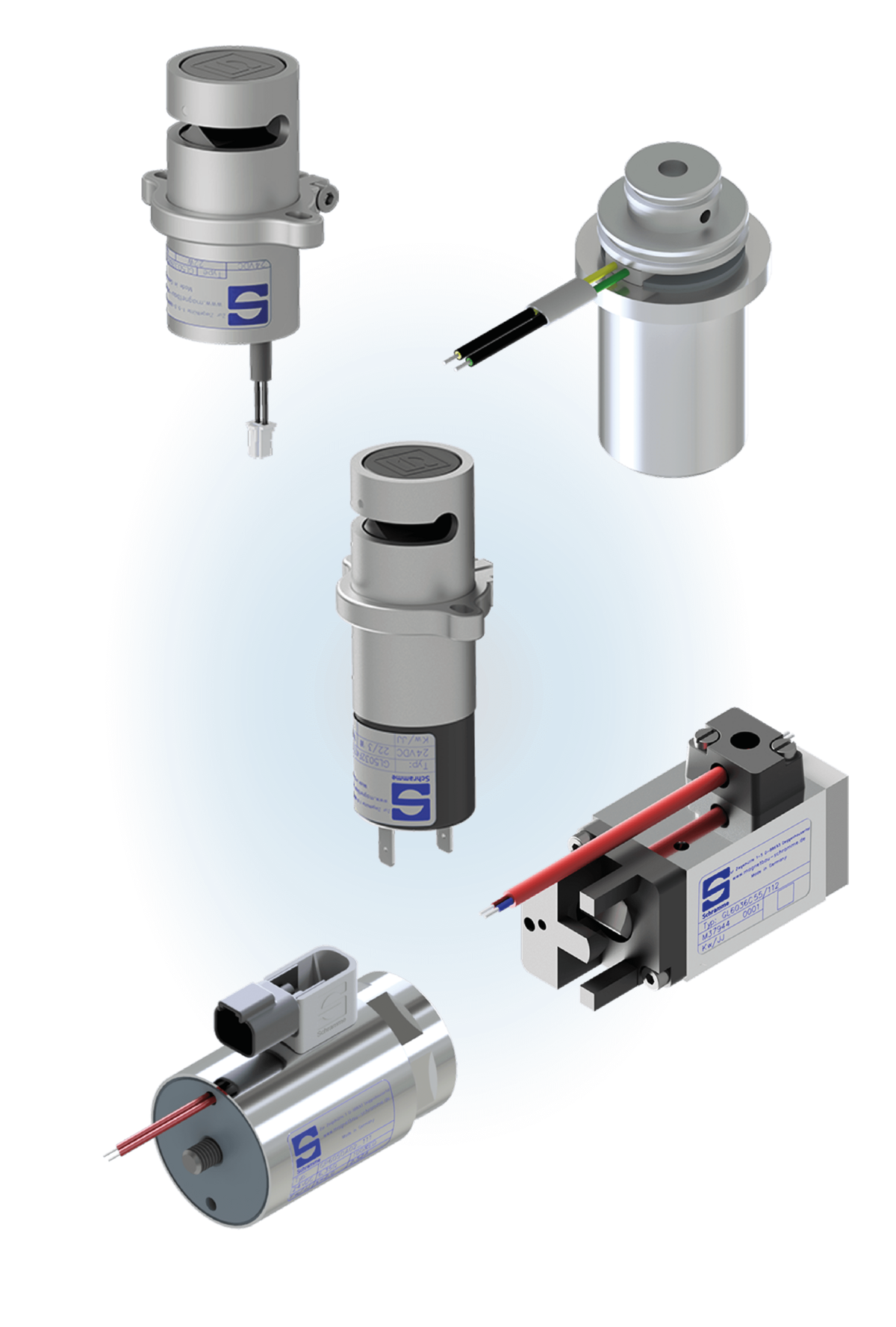

Discover a diverse selection of different solenoid valve types below.

Solenoid valves - Product details

Advantages & design of solenoid valves

Solenoid valves are individually developed by Magnetbau Schramme according to customer requirements and then manufactured in series. You can rely on our many years of experience and expertise to successfully implement your project.

Discover a diverse selection of different solenoid valve types below.

A solenoid valve typically consists of a housing, a magnetic coil, a movable armature, a sealing element and the electrical connections. The function of a solenoid valve is essentially influenced by the number of turns of the winding in the coil and the applied current, which together generate the magnetic force to control the valve. In addition, the choice of materials and the geometry of the individual components play a decisive role in ensuring efficiency and durability.

There are different types of solenoid valves, which are developed depending on the application and control requirements:

- Pinch valves provide gentle flow control without direct contact with the fluid and are ideal for medical applications.

- Seat valves guarantee a secure seal at higher pressures.

- Cartridge valves are ideal for applications where a continuous flow needs to be controlled.

- Valve solenoids enable valves to be opened and closed precisely and reliably.

These solenoid valves are used in industries such as medical technology, water treatment, automotive engineering and industrial automation, where precise and reliable control of fluids is required.

Please note

Please note that we do not have any standard products. The following solenoid valves are merely examples of customer projects realised in series.

Solenoid valves: Industries

Our industry diversity

Solenoid valves are indispensable in numerous industries: in safety technology, they ensure reliable sealing systems, while in commercial vehicles they support the control of liquids and gases in various systems. In medical technology, they enable the precise dosing and control of medicines or fluids in diagnostic and therapeutic devices, and in the food industry they are used for precise control and dosing in filling, sorting and packaging processes.

Our management system according to ISO 9001 & IATF 16949 supports us in ensuring the quality requirements during the development & production of solenoid valves.

Marco Kiene

Management | CSO

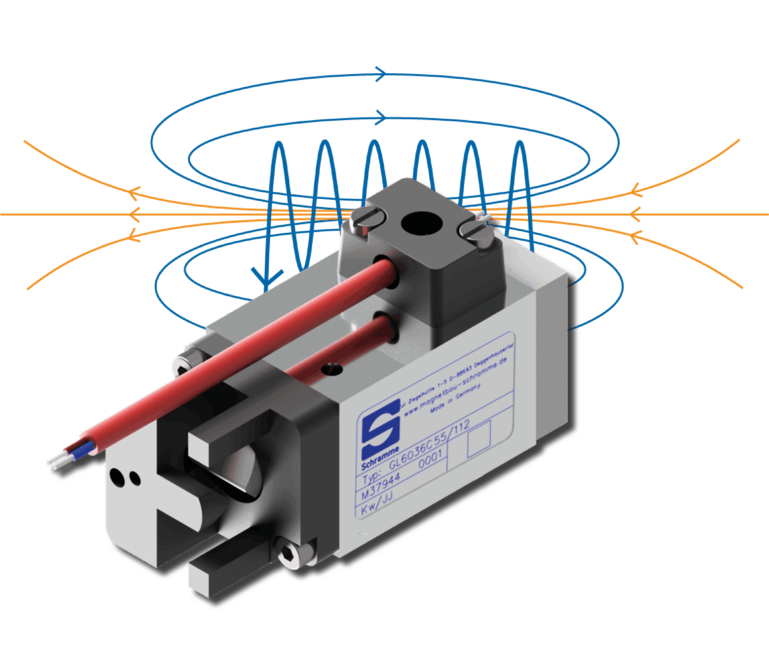

Valve solenoid application example

Steering axle for commercial vehicles

A valve solenoid in the valve block of a trailer steering axle controls precise hydraulic valves that regulate the flow of hydraulic oil.

It ensures optimum steering assistance by adjusting the actuating force of the steering depending on the speed. This results, for example, in smooth steering at low speeds and steering stability at higher vehicle speeds. In addition, the valve solenoid supports safety and assistance systems, making steering more efficient, precise and fail-safe.

More information about solenoid valves

A solenoid valve controls the flow of liquids or gases using an electromechanical principle. When a voltage is applied to the solenoid coil, a magnetic field is created which attracts the movable armature inside the valve. The armature opens or closes the valve seat, thereby precisely regulating the flow. Decisive for the function are the coil winding, the material used and the design of the valve, which enable low-friction movement and high switching speed. The solenoid valve can be customised to meet specific requirements such as high pressure ranges, extreme temperatures or special media compatibility, providing a durable and reliable solution for demanding applications.

Structure of a solenoid valve

- Housing and materials: The housing of the solenoid valve protects the internal components and is made of materials such as steel, brass or special plastics, depending on the application requirements. The choice of material influences, among other things, the corrosion resistance and determines the longevity in demanding environments.

- Solenoid coil: The solenoid coil is the centrepiece of the valve. It consists of a wire that is usually wound on a coil body. When a voltage is applied, the coil generates a magnetic field that sets the moving armature in motion and thus controls the flow of the medium.

- Armature and valve seat: The movable armature, sometimes also called a piston, is actuated by the magnetic field of the coil. The valve seat, usually made of metal or high-performance plastics, ensures reliable sealing and precisely controls the flow of media.

- Seals and spring elements: Seals made of chemically resistant materials ensure a reliable seal, while spring elements stabilise the position of the armature and ensure resetting when the magnetic field is extinguished.

- Connection and control technology: The solenoid valve has electrical connections that enable easy integration into control systems. Depending on the requirements, the valve can be direct or pilot operated in order to fulfil different pressure and flow requirements.

Advantages of solenoid valves

Solenoid valves offer precise control and high reliability, making them the ideal solution for demanding applications. Their robust design makes them resistant to faults and ensures a long service life, even under extreme conditions.

Their fast switching behaviour enables high dynamics, ideal for processes where fast and precise reactions are required. Thanks to their low number of moving parts, they are virtually wear-free and require no maintenance, which minimises operating costs.

With simple electrical control, they are easy to integrate into complex control systems. The versatile adaptability in terms of materials, protection types and explosion protection variants allows them to be used in a wide temperature and pressure range and makes them ideal for a wide variety of industries - from medical technology to industrial automation.

To summarise, the biggest advantages of solenoid valves are

- Robust design and low sensitivity to faults

- Fast switching behaviour with high dynamics

- High sealing force and reliability

- Low technical complexity compared to alternative control solutions

- Simple electrical control

- Wide operating temperature range

- Small number of moving parts

- Long service life and maintenance-free operation

- High degrees of protection and optional explosion-proof variants

- Flexible use in a wide range of industries and applications

Solenoid valves - Questions & Answers

What is the difference between a valve solenoid and a solenoid valve?

A valve solenoid is another name for a solenoid (proportional or switching version) that generates a mechanical movement to open or close a valve. A solenoid valve, on the other hand, is a complete assembly that already contains the valve solenoid as an elementary component, but also combines all valve components. Solenoid valves regulate or control the volume flow or pressure of liquids or gases. The valve solenoid is therefore part of the solenoid valve.

For which media and applications are solenoid valves suitable?

Solenoid valves are versatile and suitable for liquids and gases, even in demanding environments. Their materials and seals can be adapted to chemically aggressive or viscous media, making them ideal for applications in medical technology, the food industry, automotive technology and industrial automation. Special protection classes and options for explosion protection extend the range of applications to safety-critical areas.

What temperature and pressure ranges can solenoid valves cover?

Solenoid valves from Magnetbau Schramme are designed for large temperature and pressure ranges. They can withstand temperatures from well below freezing to well over 100°C and pressure ranges up to well over a thousand bar, depending on the design and materials used. This flexibility allows them to be used in a wide range of industrial applications, from hydraulic systems and medical devices to high-pressure applications.

Are solenoid valves maintenance-free?

Yes, solenoid valves are maintenance-free as they have a small number of moving parts that are subject to little wear. This minimises operating and maintenance costs considerably. High-quality materials and precise manufacturing techniques guarantee a long service life, even under continuous load, making them ideal for continuous use in demanding applications.

What types of protection and certifications are available for solenoid valves?

Magnetbau Schramme offers solenoid valves with various types of protection, including IP protection classes against dust and water. Explosion-proof models in accordance with ATEX and other standards can also be realised to ensure maximum safety in sensitive areas. These protection classes and certifications are particularly important for applications in the chemical, oil and gas industries and for use in safety-critical environments.

Can solenoid valves be customised to meet specific customer requirements?

Yes, Magnetbau Schramme offers customised designs and adaptations. Depending on requirements, materials, seals, housing shapes and connections can be customised to optimally meet the specific conditions of the application. In addition, control characteristics such as switching times and pressure ranges can be precisely tailored to the customer's needs to ensure maximum performance and efficiency.