Rapid development, validation & industrialisation.

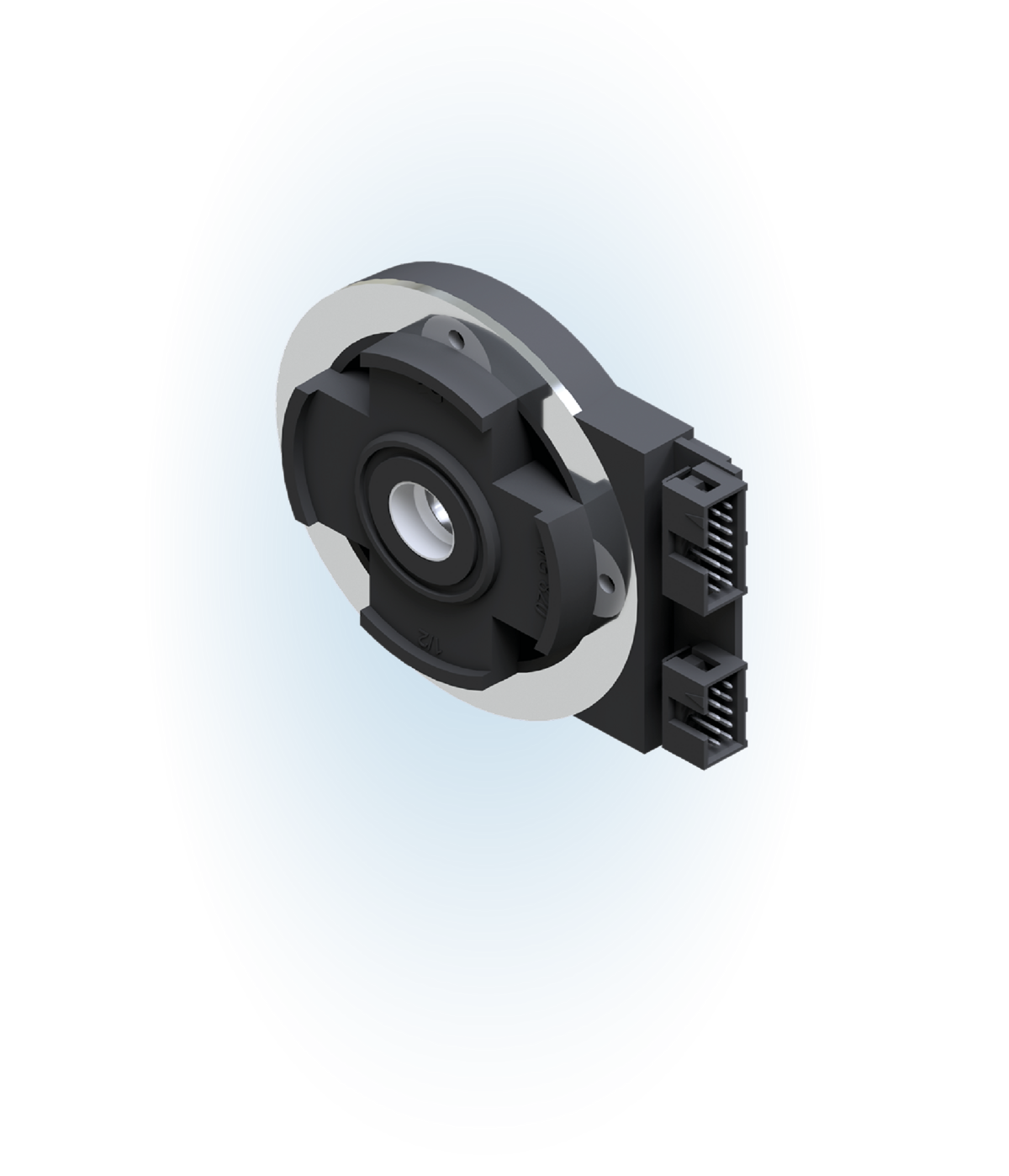

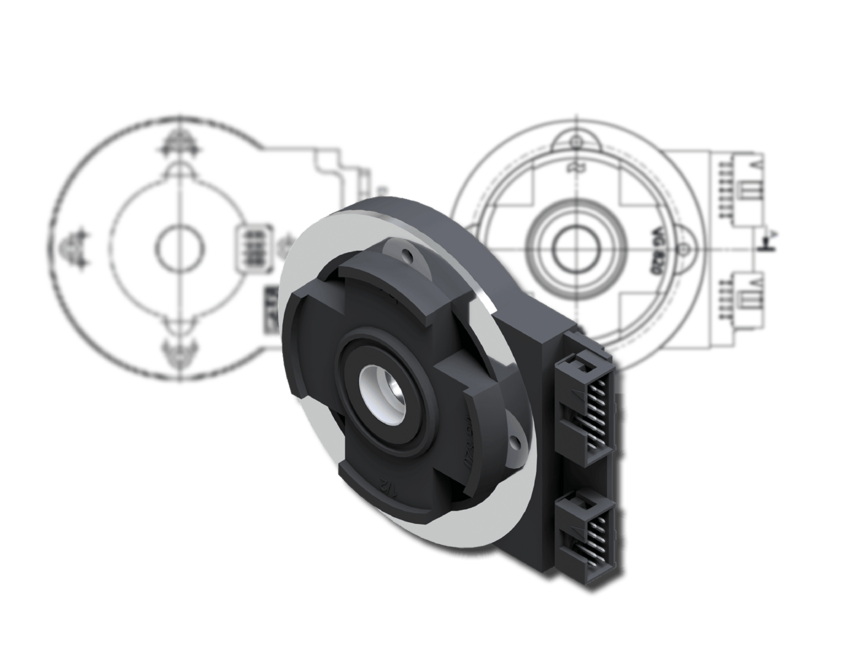

Magnetic bearing

Are you looking for a reliable partner for high-quality magnetic bearings? Then you've come to the right place! As a specialist in the development and production of customised magnetic bearings, we offer you innovative and precise solutions that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of magnetic bearings

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of magnetic bearings. With our technical expertise and many years of experience, we realise individual solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure that everything runs smoothly at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

Please note that we do not have any standard products. The following magnetic bearings are merely examples of customer projects realised in series production.

Technical data - Magnetic bearing

Experience the wealth of different possibilities.

Magnetic bearings use magnetic forces to support and stabilise a shaft without contact. Electromagnets generate a controlled magnetic field that keeps the shaft floating and minimises friction and wear. Sensors monitor the position of the shaft and a control system adjusts the magnetic field in real time to ensure stability even at high speeds.

Do you have any questions about our technical data or other details you would like to discuss? Please feel free to contact us.

| Load range | Customer specification |

| Speed range | Customer specification |

| Nominal voltage range | 6V, 12V, 24V, 36V, 48V and others |

| Protection class / protection type | up to IP6K9K |

| Electrical connection | Free stranded wires, assembled connectors, integrated (moulded) connectors, etc. |

| Special features | Integrated electronic components (active magnetic bearing) |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised magnetic bearings and further electromagnetic products.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about magnetic bearings

How magnetic bearings work

- Magnetic bearings are working due to targeted generation of magnetic fields in order to support rotating shafts in a contactless and stable manner. Electromagnets generate a magnetic field that centres the shaft and enables floating states.

- Optionally, sensors continuously measure the position of the shaft and a control system immediately adjusts the magnetic field to correct position deviations.

- This avoids mechanical friction and wear, which enables a long service life and efficiency even at high speeds and in extreme environments. In addition, vibrations can be effectively controlled, which increases the overall performance of the systems.

Designs and types of magnetic bearings

- There are two main types of magnetic bearings: active and passive bearings. Active magnetic bearings use electromagnets that are controlled by a control system to precisely stabilise the shaft.

- Passive magnetic bearings, on the other hand, work without active control and are usually based on permanent magnets, which support simple, stable applications but are less flexible.

- There are also hybrid systems that combine passive and active components to optimise stability and energy efficiency and meet different application requirements.

Performance parameters of magnetic bearings

- Resistance: The electrical resistance of the coil is decisive for the current consumption and can be influenced by the thickness of the wire and the number of windings.

- Inductance (L): Measured in Henry (H), the inductance indicates how well the coil generates a magnetic field.

- Maximum temperature: Solenoid coils are designed for specific operating temperatures, which depend on the materials used. Overheating can lead to a loss of magnetic properties or damage to the insulation.

Structure of the magnetic bearing

- Load capacity: The load capacity indicates how much weight the magnetic bearing can hold in a stable suspended state. It is a critical factor when selecting the bearing, as it determines the maximum load that the bearing can handle without destabilising the shaft or losing the levitation state.

- Stiffness: The stiffness describes how resistant the magnetic bearing is to changes in the position of the shaft. Higher stiffness leads to more precise stabilisation, as it corrects mechanical deviations or external influences, such as vibrations, more effectively and maintains an exact position of the shaft.

- Damping: Damping is the ability of the magnetic bearing to reduce oscillations and vibrations caused by rotational movements or external disturbances. Good damping properties improve running smoothness and extend the service life of the entire machine structure by minimising stresses.

- Control speed: The control speed determines how quickly the magnetic bearing system reacts to position deviations and adjusts the magnetic forces. A high control speed is crucial for dynamic applications in which quick corrections are necessary to keep the shaft stable at all times.

- Maximum speed: The maximum speed describes the highest rotational speed that the magnetic bearing can stably support. It is an essential parameter for high-speed applications, as the bearing remains stable when this limit is reached without sacrificing precision or reliability.

Magnetic bearing applications

- Turbomachinery: In compressors, turbines and pumps, magnetic bearings enable high speeds and minimise friction and wear. They are ideal for use in sensitive environments, such as the oil and gas industry, where high reliability is required.

- Medical technology: Magnetic bearings are used in MRI machines and blood centrifuges due to their contactless bearings. They enable vibration-free, precise and hygienic applications without particle abrasion, which is particularly important for sterile environments.

- Power generation: In generators and wind turbines, magnetic bearings offer a durable, low-maintenance solution. The contact-free bearing reduces downtime and extends the service life, which is a great advantage in energy production.

- Vacuum and clean room technology: In semiconductor and coating systems, magnetic bearings prevent contamination from lubricants or abrasion. Their non-contact operation is ideal for applications where a clean environment is essential.

Environmental requirements Magnetic bearings

- Magnetic bearings must fulfil high environmental requirements such as IP protection and temperature resistance. High IP protection (e.g. IP67) protects against dust and water, which is essential in harsh industrial environments. In addition, they are often designed for operating temperatures of up to 150 °C or higher in order to remain stable even in extreme heat. This robustness increases the reliability and longevity of the bearings in demanding applications.

Magnetic bearings - Questions & Answers

How do magnetic bearings work and what advantages do they offer over conventional bearings?

Magnetic bearings stabilise rotating shafts using magnetic forces that allow the shaft to float without contact. Electromagnets generate a controlled magnetic field that is adjusted by sensors and control systems to precisely centre the shaft. They offer considerable advantages over mechanical bearings: no friction, no wear and reduced maintenance costs. The contact-free bearing enables higher speeds and extends the service life as no mechanical parts are directly loaded.

How maintenance-intensive are magnetic bearings compared to conventional bearings?

Magnetic bearings are extremely low-maintenance, as they operate without contact and therefore exhibit neither friction nor mechanical wear. Unlike mechanical bearings, magnetic bearings do not need to be lubricated or replaced regularly. This property significantly reduces downtimes and maintenance costs and is particularly advantageous in systems with components that are difficult to access or critical operating conditions.

What are the requirements for the energy supply of magnetic bearings?

Magnetic bearings require a continuous supply of energy to operate the electromagnets and the control system. The exact power consumption depends on the application, but is optimised for energy-efficient operation. The power supply should be reliable, as the levitation state of the shaft can be lost in the event of interruptions. In safety-critical applications, emergency power systems are often used to ensure safe operation even in the event of a power failure.

What load capacity do magnetic bearings offer and how does this affect the application?

The load capacity of magnetic bearings depends on the size and design and determines the maximum load that the bearing can stably support. A higher load capacity is advantageous for applications with larger or heavier rotating components, such as in turbomachinery or generators. The load capacity is decisive for the selection of a suitable bearing and ensures stable operation even under high loads.

Can magnetic bearings also be used in clean rooms?

Yes, magnetic bearings are ideal for cleanrooms as they operate without contact and therefore do not generate any abrasion or lubricant residue. Their design enables clean operation without the risk of contamination, which is particularly important in semiconductor and medical technology. As no particles are released, they fulfil strict cleanroom requirements and help to maintain the cleanroom class, enabling their use in sensitive environments.

How do magnetic bearings react to vibrations and external disturbances?

Magnetic bearings offer excellent damping properties and effectively reduce vibrations as they are not mechanically supported. The control system constantly adjusts the magnetic field to compensate for external disturbances and keep the shaft stable. This ensures smooth running and precision, even in environments with high vibrations or variable loads, which increases the performance and service life of the bearing and the entire system.