Rapid development, validation & industrialisation.

Electromagnetic brakes

Are you looking for a reliable partner for high-quality electromagnetic brakes? Then you've come to the right place! As a specialist in development and manufacturing of customised brake solutions, we offer you innovative and precise products that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of electromagnetic brakes

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of electromagnetic brakes. With our technical expertise and many years of experience, we realise individual solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure that everything runs smoothly at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

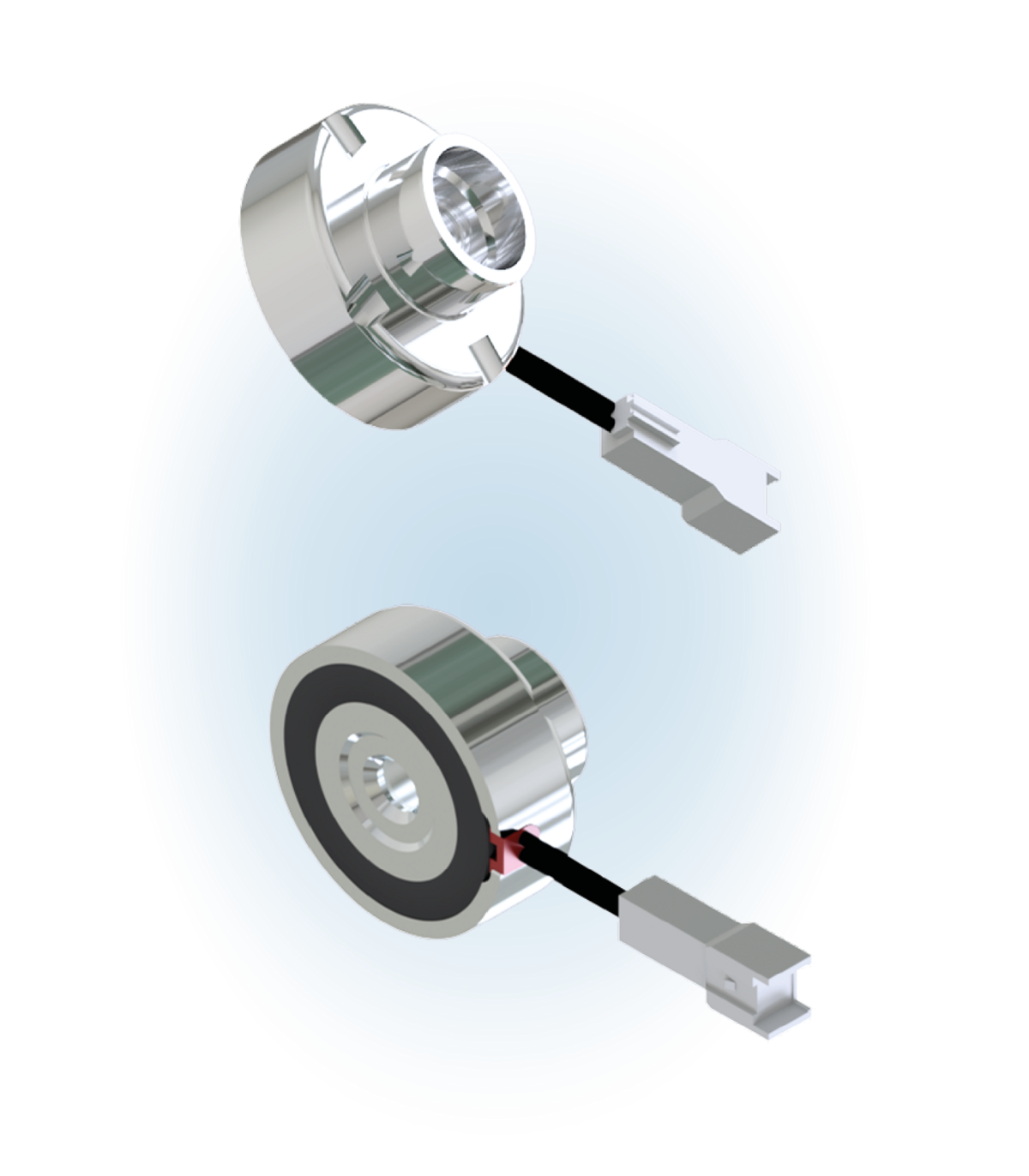

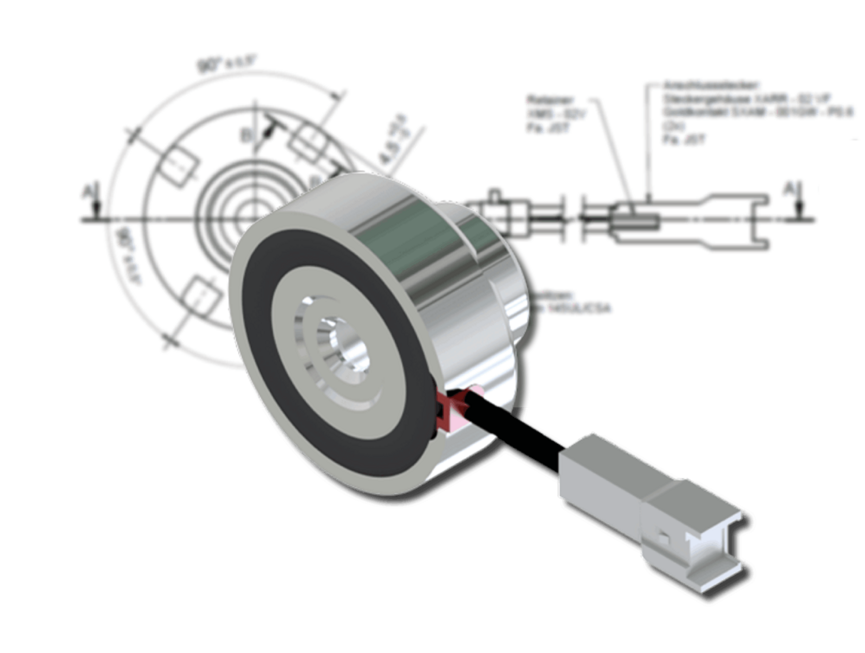

Please note that we do not have any standard products. The following electromagnetic brakes are merely examples of customer projects realised in series production.

Technical data - Electromagnetic brakes

Experience the wealth of different possibilities.

An electromagnetic brake offers precise and fast braking by means of a specifically generated magnetic field. When power is applied, friction is generated that brings moving parts to a controlled standstill - ideal for applications that require maximum reliability and efficiency. When the power is switched off, the brake is released automatically so that operation can continue smoothly.

Do you have any questions about our technical data or other details you would like to discuss? Please feel free to contact us.

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised electromagnetic products.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

Further information about electromagnetic brakes

How an electromagnetic brake works

- An electromagnetic brake uses an electric magnetic field to control mechanical movement. When current is supplied, an electromagnet is activated which attracts a braking surface, such as a disc or drum, and thus generates friction. This friction slows or stops the movement precisely and reliably. When the current is switched off, the magnetic field is released and the brake releases the mechanical component again. Electromagnetic brakes are particularly suitable for machines and systems that require fast, safe braking and immediate resumption of movement.

Designs and types of electromagnetic brakes

- Electromagnetic brakes vary in design depending on the type and requirements. Disc brakes consist of a solenoid coil and a rotating brake disc; they are compact and suitable for precise control.

- Drum brakes have a robust drum design with a higher friction torque and are ideal for applications with high braking requirements. Powder-coated brakes utilise a magnetic powder as a friction medium to provide smooth braking, especially at variable speeds.

- Spring-applied brakes are designed to remain applied without power; their spring mechanism ensures that they are only released when power is applied, making them particularly safe.

Performance parameters electromagnetic brake

- Holding and braking torque: Determines the force with which the brake holds or stops a load and is crucial for applications with high loads and precise stopping requirements.

- Response time: The time it takes for the brake to activate or release. A fast response time is important for dynamic applications.

- Wear resistance: Measures the service life and resistance of the brake under continuous load and high cycles, which influences the maintenance intervals.

- Thermal resistance: The ability of the brake to withstand and dissipate heat is critical for applications with high speeds or frequent braking cycles.

Structure of the electromagnetic brake

- Housing: Protects the internal components and ensures stability and thermal dissipation of the heat generated.

- Copper coil: Generates a magnetic field when current flows and is the heart of the brake.

- Armature plate: Is attracted by the magnetic field and moves in contact with the friction surface to generate the braking torque.

- Friction surface: This component provides the actual braking effect through friction, usually in the form of a brake disc or drum.

- Spring mechanism (for spring-applied brakes): Keeps the brake closed when de-energised and opens when power is applied.

Applications electromagnetic brake

- Lifts and lifts: Electromagnetic brakes ensure safe stopping and emergency braking in lifts and lifts. They ensure that the car stops immediately in the event of power failures or other faults to guarantee the safety of passengers. The fast response time enables a smooth stop, which increases comfort.

- Conveyor systems: In conveyor systems, electromagnetic brakes regulate the speed and position of goods on conveyor belts. They enable precise stopping and starting, which is crucial for efficient production processes. The brakes can also be activated immediately in the event of sudden malfunctions or stop signals to prevent damage to materials and machines.

- Industrial robots: In robotics, electromagnetic brakes ensure precise control and positioning of moving parts. They enable fast movements and immediate stopping, which is crucial for tasks such as assembly, packaging and material handling. The reliability of these brakes contributes to the overall performance and safety of robotic applications.

- Cranes and hoists: Electromagnetic brakes are often used in cranes and hoists to hold loads safely and lower them in a controlled manner. They offer high braking force and reliability, which is particularly important in applications with heavy loads and frequent movements. The brakes ensure that the loads can be positioned precisely and stop immediately in an emergency.

Environmental requirements for electromagnetic brakes

- Electromagnetic brakes must fulfil environmental requirements such as a temperature resistance of -40 °C to +150 °C in order to work reliably. Sufficient moisture and dust resistance is also required to ensure functionality in demanding environments. Corrosion-resistant materials are crucial for the service life of the brakes. They should also be able to withstand vibrations and shocks in industrial applications. In addition, electromagnetic compatibility (EMC) is important to avoid interference with other electronic devices.

Electromagnetic brake - Questions & Answers

What is the difference between a brake solenoid and an electromagnetic brake?

A brake solenoid is an electromagnet that indirectly activates a brake by controlling mechanical components. It is often used in machines and vehicles to precisely stop or hold moving parts. An electromagnetic brake, on the other hand, is already flanged directly to the rotating component and thus combines the brake and the associated electromagnetic actuator. It is typically used in electric drives and industrial applications, as it enables precise and safe stopping.

What are the advantages of electromagnetic brakes?

Electromagnetic brakes offer several advantages, including high reliability, fast response times and precise control. They are able to generate large braking forces in a compact design. They also enable smooth stopping without mechanical wear and are low-maintenance as they have few moving parts.

What safety features do electromagnetic brakes have?

Electromagnetic brakes are equipped with several safety features, such as the ability to brake immediately in the event of a power failure. They also often fulfil international safety standards, making them ideal for safety-critical applications in industry and transport.

How is the performance of an electromagnetic brake tested?

The performance of electromagnetic brakes is checked using various tests, including holding and braking torque tests as well as temperature and load tests. These tests ensure that the brakes function reliably under realistic operating conditions. End-of-line tests are also carried out to guarantee the quality and performance of each brake before delivery.

How long do electromagnetic brakes last?

The service life of electromagnetic brakes depends on various factors, such as the quality of the materials used, the environmental conditions and the frequency of use. As a rule, high-quality electromagnetic brakes can last for many years, especially if they are operated in suitable applications and under optimum conditions. Regular maintenance can also extend the service life.