Rapid development, validation & industrialisation.

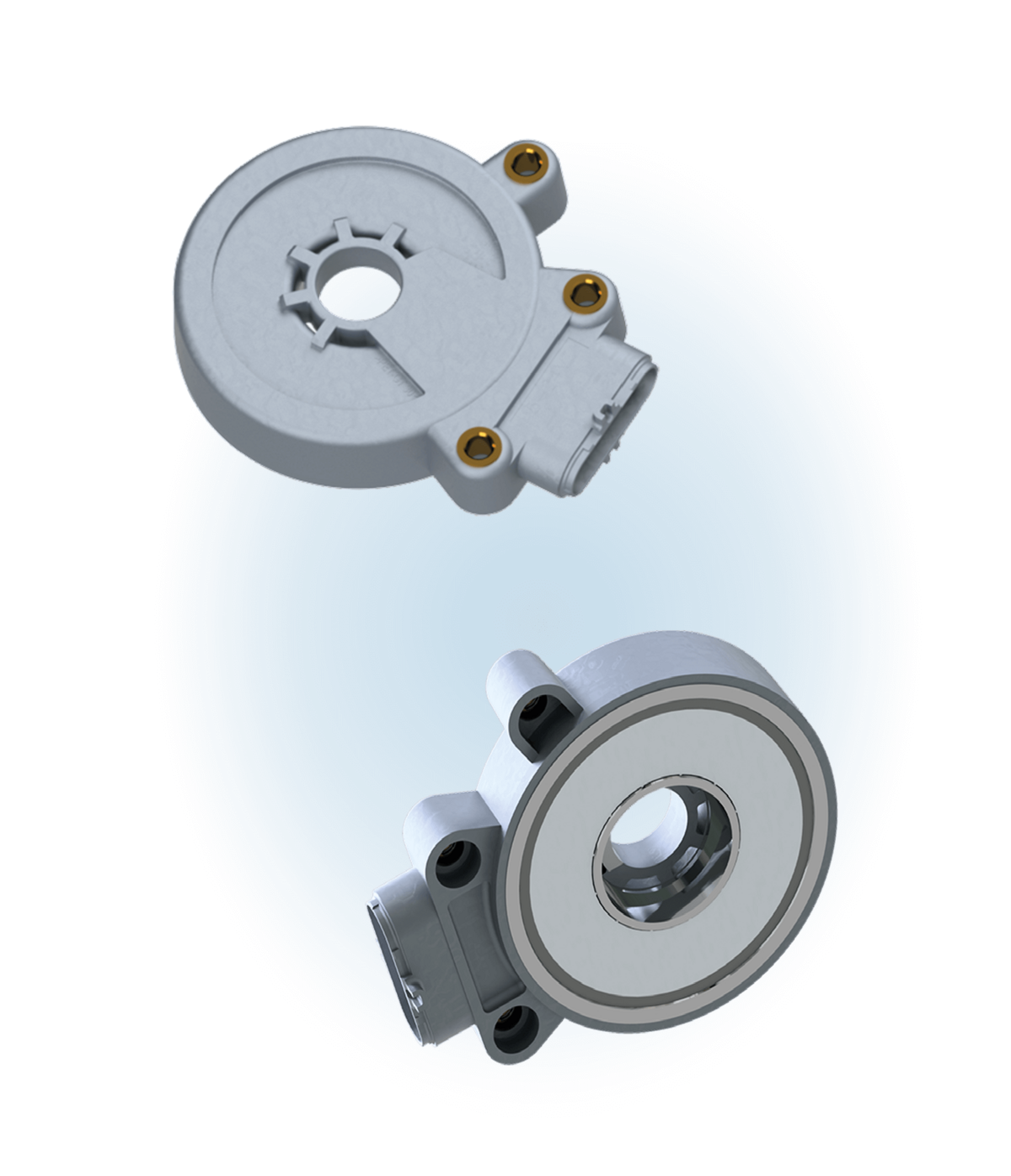

Electromagnetic clutch

Are you looking for a reliable partner for high-quality electromagnetic clutches? Then you've come to the right place! As a specialist in the development and production of customised electromagnetic clutches, we offer you innovative and precise solutions that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of electromagnetic clutches

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of electromagnetic clutches. With our technical expertise and many years of experience, we realise individual solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure that everything runs smoothly at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

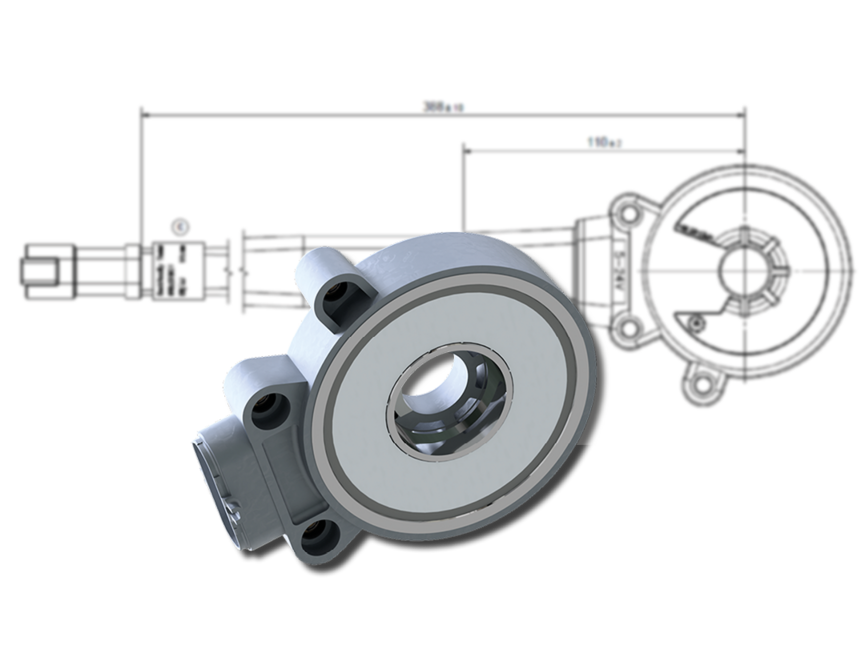

Please note that we do not have any standard products. The following electromagnetic clutches are merely examples of customer projects realised in series production.

Technical data - Electromagnetic clutch

Experience plenty of different possibilities.

An electromagnetic clutch uses a magnetic field to connect or disconnect a rotating shaft. When current is applied to a solenoid coil, it generates a magnetic field that attracts an armature plate (usually made of iron) and establishes the connection to the driven shaft. When the current is switched off, the magnetic field disappears and the clutch disengages. This design allows precise and fast switching, is frequently used in industrial machines and vehicles and enables low-wear power transmission.

Do you have any questions about our technical data or other details that you would like to discuss? Please do not hesitate to contact us.

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised electromagnetic products.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about electromagnetic clutches

How an electromagnetic clutch works

- An electromagnetic clutch uses a coil to generate a strong magnetic field that attracts a ferromagnetic armature disc. The armature disc can move axially and is pressed against a rotating friction disc as soon as the magnetic field is built up. This contact pressure causes a frictional force transmission between the two discs, whereby the torque is transmitted to the output shaft.

- When the current is switched off, the magnetic field is reduced and the restoring force of a spring separates the armature disc. This design enables fast shifting and controlled torque transmission in dynamic application environments.

Electromagnetic clutch designs and types

- Electromagnetic clutches are mainly available as dry clutches and wet clutches. Dry clutches transmit torque by frictional engagement and offer fast switching times, but are suitable for lower speeds.

- Wet clutches operate in a lubricating medium that dissipates heat and reduces wear, ideal for high speeds and continuous use. Designs include powder clutches (for even slip) and magnetic clutches without mechanical connection for completely wear-free applications.

Performance parameters Electromagnetic clutch

- Torque: Maximum force the clutch can transmit before slipping. Decisive for the suitability of the clutch for specific load requirements.

- Switching time: Time required for engagement or disengagement, influenced by the magnetic field structure and the mobility of the armature plate. Relevant for fast and precise switching operations.

- Operating speed: Maximum speed at which the clutch can still operate safely and efficiently. Dependent on design and cooling options.

- Wear resistance: Determines the service life, especially for friction clutches, which are more susceptible to material wear. Important for maintenance intervals.

- Duty cycle: Proportion of the operating time during which the clutch is activated. High ED values mean frequent activation, e.g. for continuous drives.

- Current consumption: Electrical current required by the coil to build up the magnetic field. Influences the efficiency and heat development of the clutch.

Structure of the electromagnetic clutch

- Housing: Protects the internal mechanics and ensures the necessary alignment and stability of the components.

- Solenoid coil: A coil that generates a magnetic field when electric current is applied. This is usually fixed in the housing and is activated by a power supply.

- Armature plate: A ferromagnetic component that is attracted by the magnetic field and establishes the connection to the friction disc. It is axially movable and couples the rotating shafts.

- Rotor: The rotor carries the solenoid coil and rotates together with the drive shaft. It is designed in such a way that the magnetic field is efficiently transferred to the armature plate.

- Spring mechanism: This releases the connection as soon as the power supply to the solenoid coil is interrupted. The spring ensures that the armature plate returns to its original position when the magnetic field drops.

Applications Electromagnetic clutch

- Electromagnetic clutches are used in numerous industrial and automotive applications as they enable precise and fast power transmission.

- In machine tools and production systems, they regulate rotary movements by selectively connecting or disconnecting drive and working shafts, enabling precise control in automated processes.

- In conveyor technology, they are used to switch conveyor belts and drives on and off in a controlled manner, allowing flexible control of material flows.

- In the automotive sector, especially in start-stop systems and hybrid vehicles, electromagnetic clutches ensure efficient engine control and fuel savings.

- They can also be found in office equipment such as printers and photocopiers, where they ensure targeted movements and drive transmissions.

Environmental requirements for electromagnetic clutches

- Electromagnetic clutches must fulfil specific environmental requirements to ensure reliable performance. These include temperature resistance from -40 °C to +150 °C as well as high moisture and dust resistance, which is ensured by suitable protection classes. Corrosion-resistant materials are crucial for the longevity of the couplings, while they must also be able to withstand vibrations and mechanical shocks in industrial applications. In addition, electromagnetic compatibility (EMC) is important to prevent interference with other electronic devices.

Electromagnetic clutch - Questions & Answers

What electrical requirements must be observed during installation?

When installing electromagnetic clutches, specific electrical requirements must be observed to ensure optimum function. These include the correct rated voltage and current requirement, which must correspond to the clutch. Wiring should be done properly to avoid short circuits or overheating. The use of suitable protective devices, such as fuses or switches, is also recommended. The ambient temperature and the possible influence of electromagnetic interference should also be taken into account in order to maximise reliability and safety.

How do different types of electromagnetic clutches differ?

There are different types of electromagnetic clutches, including permanent and temporary clutches. Permanent clutches are permanently activated as long as current is flowing, while temporary clutches can be switched on and off as required. Clutches also differ in design, such as disc or drum design, which affects their application and performance. Each design has specific advantages, depending on the desired performance, space requirements and application requirements.

Can electromagnetic clutches be used in different environments?

Yes, electromagnetic clutches are designed for use in various environments. They can be used in industrial applications, automation technology and in food and medical technology. They can be realised in various protection classes to protect them from dust, moisture and chemical influences. They are also available in different temperature ranges so that they can work reliably even under extreme conditions.

What role does temperature control play in electromagnetic clutches?

Temperature control is critical to the performance and longevity of electromagnetic clutches. High temperatures can affect the function of the clutch and cause the coil to overheat, which can lead to failure. To avoid this, suitable cooling methods and temperature-resistant materials should be used. It is also important to regularly monitor the ambient temperature and operating conditions. Some systems are equipped with temperature sensors that issue alarm messages if critical temperatures are exceeded.

What does the maintenance of electromagnetic clutches look like?

The maintenance of electromagnetic clutches includes regular inspections and tests to ensure that all components are functioning properly. This includes checks for wear, corrosion and damage. It is important to check the electrical connections and adjust them if necessary. Cleaning the clutch of dust and dirt is also necessary to ensure smooth operation. The manufacturer's recommendations for maintenance should be followed to maximise the service life of the couplings and minimise downtime during operation.