Rapid development, validation & industrialisation.

Solenoid coil

Are you looking for a reliable partner for high-quality solenoid coils? Then you've come to the right place! As a specialist in the development and production of customised solenoid coils, we offer you innovative and precise solutions that are perfectly tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of solenoid coils

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of solenoid coils. With our technical expertise and many years of experience, we realise individual solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and ensure that everything runs smoothly at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

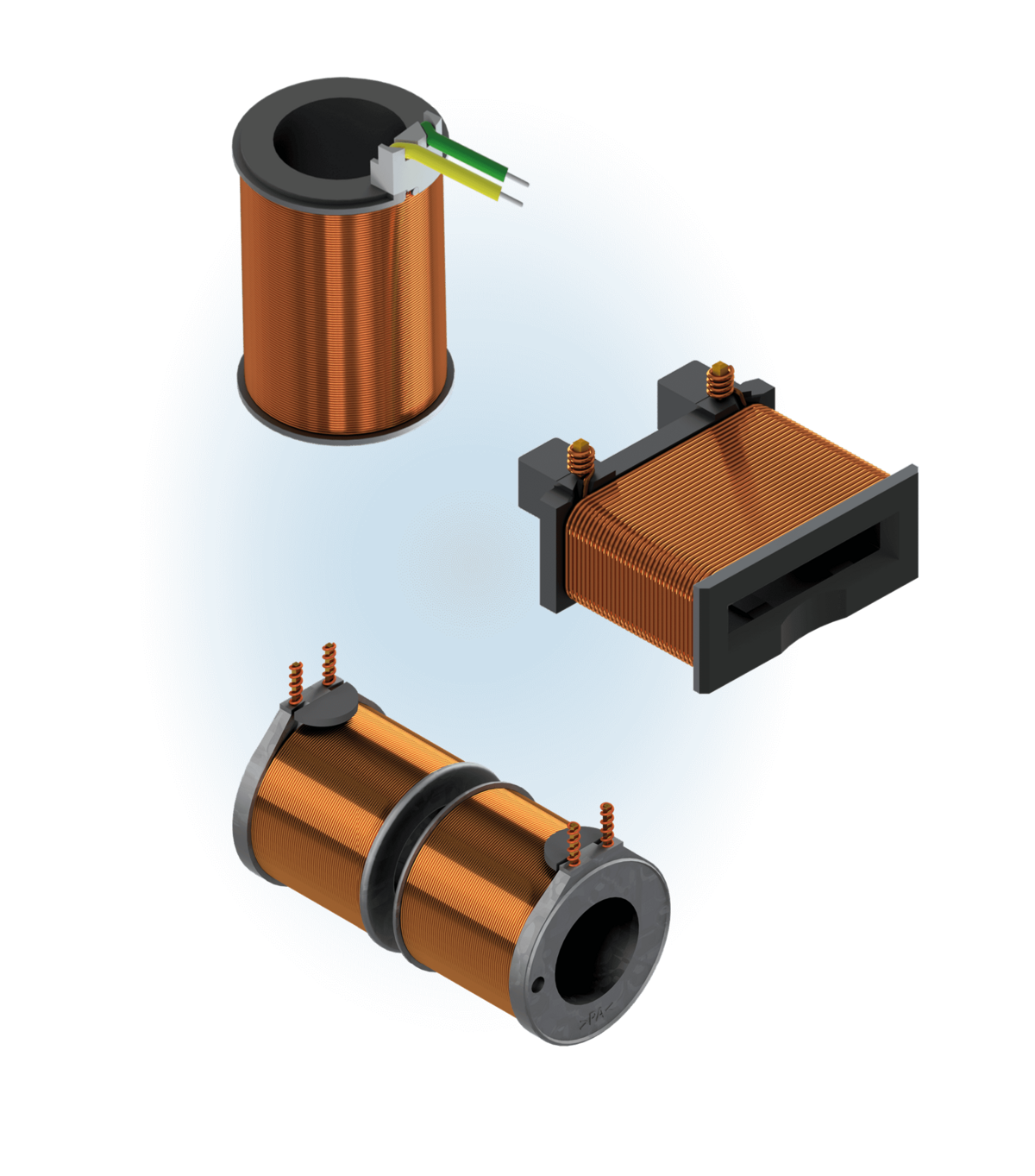

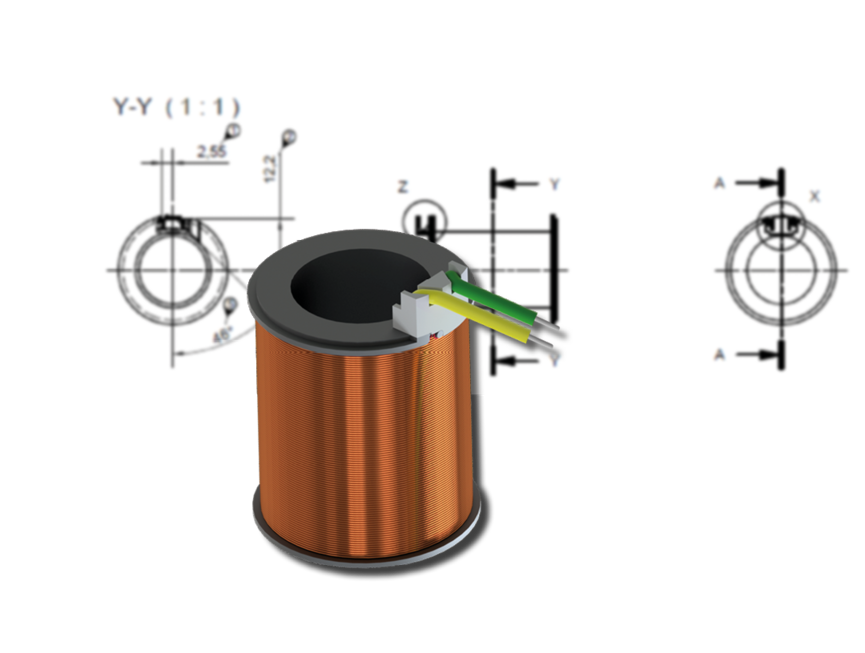

Please note that we do not have any standard products. The following solenoid coils are merely examples of customer projects realised in series production.

Technical data - Solenoid coils

Experience the wealth of different possibilities.

A solenoid coil consists of a copper wire wound around a plastic bobbin, which generates a strong magnetic field when an electric current is applied. It is often used in applications such as relays, electromagnets and actuators to control mechanical movements or switch electrical signals.

Do you have any questions about our technical data or other details you would like to discuss? Please feel free to contact us.

| Design | Optimised filling level due to orthocyclic winding |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Wire diameter | from 0.1mm to 1.5mm |

| Temperature range | up to 220°C |

| Electrical connection | Free stranded wires, assembled connectors, integrated (moulded) connectors, etc. |

| Special features | Overmoulded / encapsulated / bandaged etc. / integration of electronic components |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised solenoids coils.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about solenoid coils

How solenoid coils work

- Solenoid coils work by applying an electric current to a wire winding. A magnetic field is generated by the energisation. This magnetic field is often used to trigger mechanical movements or switching operations.

- When the current flows through the coil, these movements can, for example, actuate a switch or attract a device, enabling various electrical and mechanical applications. As soon as the current is switched off, the magnetic field disappears and the solenoid coil returns to its original state, ensuring fast responsiveness for repeated applications.

Designs and types of solenoid coils

- Solenoid coils are available in various designs, including cylindrical, flat, toroidal and tubular coils, each catering for specific applications and requirements. Cylindrical solenoid coils are the most common design and are often used in relays and actuators, while toroidal coils have lower magnetic losses due to their shape and are used in transformers. In addition, coils with iron cores can increase the magnetic field strength, which makes them ideal for electromagnets and motors.

Solenoid coil performance parameters

- Resistance: The electrical resistance of the coil is decisive for the current consumption and can be influenced by the thickness of the wire and the number of turns.

- Inductance (L): The inductance of a coil is an important electrical parameter that indicates how well the coil is able to store electromagnetic energy when an electric current flows through it. It is often measured in Henry (H).

- Maximum temperature: Solenoid coils are designed for specific operating temperatures depending on the materials used. Overheating can lead to damage to the copper wire insulation and thus to functional failure.

Structure of the solenoid coil

- Copper wire: The wire is usually made of copper, as it has a high electrical conductivity, which influences the efficiency of the solenoid coil. The wire is often insulated to prevent short circuits between the windings.

- Coil former: The wire is wound around a coil former, which can be made of plastic or other insulating materials. These materials are important for concentrating the magnetic field and optimising the electrical properties.

- Core material: Many magnetic coils use a ferromagnetic core (e.g. made of iron or an iron alloy) to concentrate the generated magnetic field. The core ensures a higher magnetic flux density, which increases the efficiency of the coil.

Solenoid coil applications

- Electromagnets use solenoid coils to generate a strong magnetic field by applying an electric current, which enables a wide range of applications, such as in automation technology and mechanical engineering. They are often used to pull or push moving parts, enabling precise control of mechanisms in machines and devices.

- Electromagnets are also used in safety and holding devices, where they temporarily hold objects in place until the power is switched off.

Other applications:

- Relays: Solenoid coils are used in relays to control electrical contacts. When current flows through the coil, a magnetic field is generated that actuates a switch.

- Actuators: In automation technology and robotics, solenoid coils are used in actuators to control mechanical movements.

- Transformers: In transformers, solenoid coils are important for regulating voltage and controlling the flow of energy.

Environmental requirements for solenoid coils

- Solenoid coils must fulfil environmental requirements such as temperature resistance from -40 °C to +150 °C as well as sufficient moisture and dust resistance in order to function reliably. Corrosion-resistant materials are crucial for the service life, and the coils should be able to withstand vibrations and shocks in industrial applications. Electromagnetic compatibility (EMC) is also important to avoid interference with other electronic devices, while environmentally friendly materials and production processes are becoming increasingly important.

Solenoid coils - Questions & Answers

What is the difference between a solenoid coil and an excitation system?

A solenoid coil is a component that consists of, among other things, a wound coil body and generates a magnetic field when an electric current flows through it; it is often used in electrical and electromagnetic applications such as relays and actuators. In contrast, an excitation system refers to the entire system for generating a magnetic field, which, in addition to the solenoid coil, also includes additional components that form the magnetic circuit and concentrate the magnetic field, for example.

How does the assembly of solenoid coils in electromagnets work?

The installation of solenoid coils in electromagnets is done by integrating the coil into a housing that ensures a secure connection and the correct distance to the moving parts to ensure efficient operation of the electromagnet.

What is the significance of the windings and the number of windings in solenoid coils?

The number of windings of a solenoid coil significantly influences the strength of the magnetic field generated; the more windings there are, the greater the magnetic field at the same current flow. A higher number of windings also increases the inductance of the coil. However, too many turns can lead to increased resistance and therefore to a loss of energy, which is why a balanced ratio between the number of turns and the application is required.

How is a solenoid coil tested?

A solenoid coil is usually tested by measuring the electrical resistance of the windings to ensure that there are no interruptions or short circuits. In addition, the coil can be tested under voltage to check the correct functioning of the generated magnetic field and to ensure that it provides the required power in the intended application.

What factors influence the performance of a solenoid coil?

The performance of a solenoid coil depends on several factors, including the number of turns, which directly influences the strength of the magnetic field generated; more turns lead to a stronger magnetic field with the same current flow. In addition, the diameter of the wire plays a role, as a thicker wire improves the current flow and at the same time reduces heat generation. Another factor is the quality of the winding, which must ensure that the coil has a uniform inductance and works efficiently.