Rapid development, validation & industrialisation.

Valve solenoids

Are you looking for a reliable partner for high-quality valve solenoids? Then you've come to the right place! As experts in the development and manufacture of customised valve solenoids, we offer you innovative and precise solutions that are optimally tailored to your individual requirements.

You can rely on our many years of experience and expertise to make your project a success.

Development and production of valve solenoids

Our performance and expertise. Your success.

Magnetbau Schramme is your reliable partner for the development and series production of valve solenoids. With our technical expertise and many years of experience, we implement customised solutions that are precisely tailored to your specific requirements. We support you from the initial concept phase through to series production and guarantee a smooth process at every stage of the development process.

Contact us today and let our experts advise you individually.

Please note!

Please note that we do not have any standard products. The following valve solenoids are merely examples of customer projects realised in series production.

Technical data - Valve solenoids

Experience plenty of different possibilities.

A valve solenoid is an electromagnetic component that is used in valves to control the flow of liquids or gases. It consists of a coil and a movable armature that is actuated by magnetic force when current flows through the coil. This movement causes the valve solenoid to open or close the valve, enabling precise and fast control of the medium.

Do you have any questions about our technical data or other details you would like to discuss? Please do not hesitate to contact us.

| Construction size | No limitation, up to a max. construction weight of 15kg. |

| Nominal voltage range | 6V, 12V, 24V, 36V and others |

| Magnetic stroke | up to 20mm |

| Force | up to 200N |

| Protection class / protection type | up to IP6K9K |

| Electrical connection | Free stranded wires, assembled connectors, integrated (moulded) connectors, etc. |

| Special features | Friction-optimised (minimum hysteresis), hydraulic and pneumatic applications, definable force-stroke curve, high pressure tightness |

Development & series production

Magnetbau Schramme is your specialist in the development and production of customised valve solenoids.

Alexander Grischin

Sales Manager

- Requirements analysis

- Feasibility assessment

- Product concept

- Calculation, simulation

- Individual parts, assemblies

- Final assembly

- Functional test

- Proof of technical suitability

- Tools, equipment

- Quality, logistics

- Procurement, production

- Assembly, EOL testing

More information about valve solenoids

How a valve solenoid works

A valve solenoid works on the basis of the electromagnetic principle and controls the flow in valve systems through targeted armature movements.

- It consists of a coil wound from an insulated copper wire, a ferromagnetic core and a movable armature. When an electric current flows through the coil, the magnetic field generates an attractive force on the armature. This moves in the direction of the core and thus executes a linear movement that opens or closes the valve.

- The design allows precise control of the movement: A spring ensures that the armature returns to its starting position when the power is switched off. The path of the armature, also known as the stroke, is decisive for the opening and closing process of the valve. Depending on the design, the solenoid can operate a directly controlled (without intermediate steps) or pilot-controlled (with pressure amplification) valve. To increase efficiency, materials with high magnetic conductivity and minimised air gaps are often used to reduce the energy requirement and achieve a fast switching speed.

Designs and types of valve solenoids

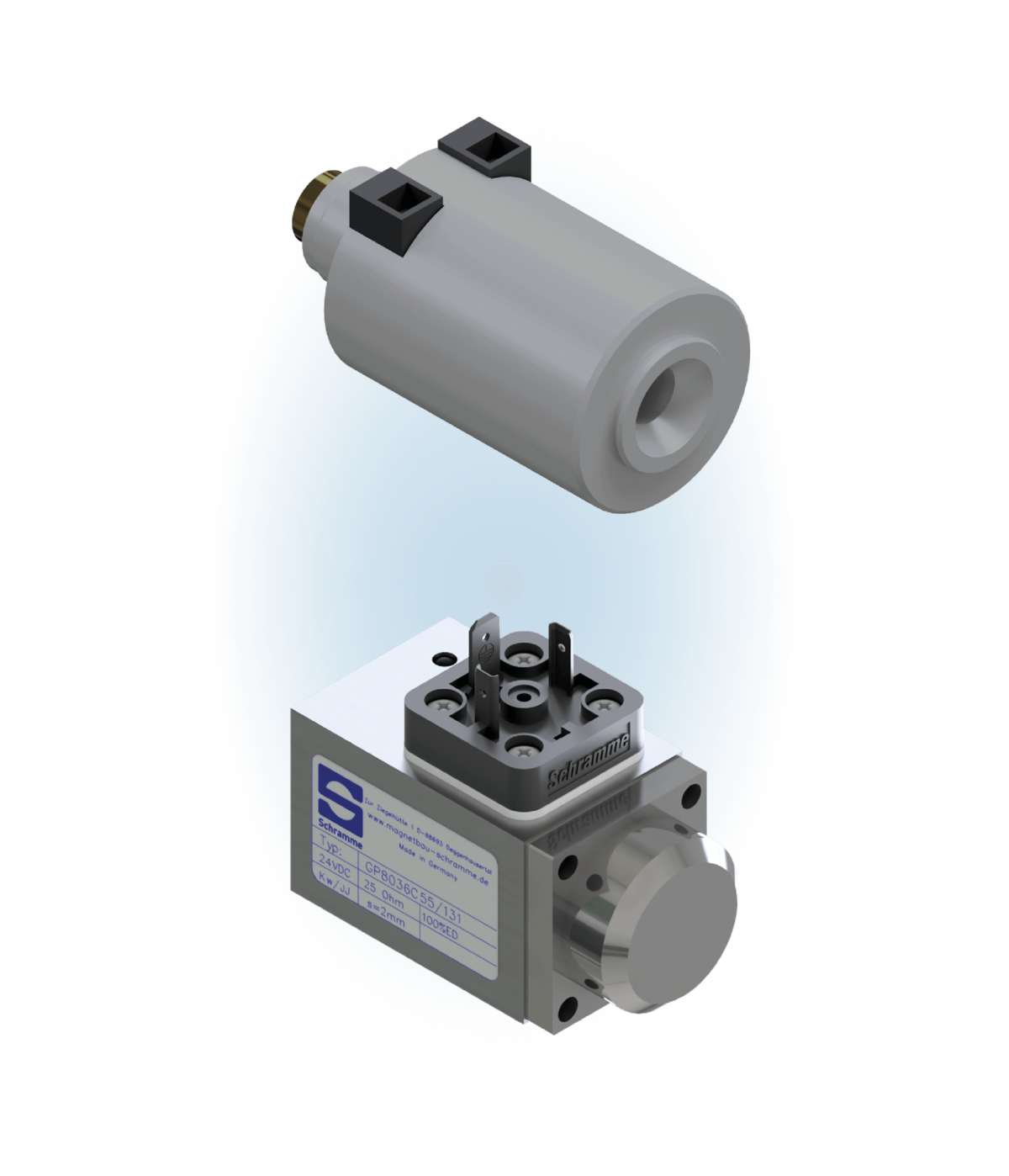

- Valve solenoids with rectangular housing: These solenoid valves have a rectangular cross-section and are particularly suitable for applications with limited installation space thanks to their compact design. They can be easily integrated into various customer applications and offer reliable control of the flow direction and quantity.

- Valve solenoids with round housing: These valve solenoids have a cylindrical cross-section and are often more cost-efficient as they can be manufactured with moulded housing components using less material.

Valve solenoid performance parameters

- Magnetic force: Determines the strength with which the solenoid armature is moved. A high magnetic force enables fast opening and closing and influences the control precision of the valve.

- Duty cycle: Specifies how long the valve solenoid can remain activated within a time interval without overheating. The duty cycle is usually given as a percentage (e.g. 100% duty cycle for continuous operation).

- Operating pressure range: Indicates the pressure range in which the valve solenoid operates reliably. A correct pressure range is crucial for the solenoid to perform its function without pressure loss or overload.

- Voltage and current consumption: These are the values of the valve solenoid's electrical supply, e.g. 24 V DC or 230 V AC.

- Response time: The time the valve solenoid needs to open or close completely. A short response time increases the responsiveness and precision of the overall system.

- Service life (operating cycles): The number of cycles that the solenoid can reliably perform before usage damage occurs. High-quality materials and design increase the service life and reduce maintenance costs.

Structure of the valve solenoid

- Housing: The housing encloses all the components of the valve solenoid and provides mechanical protection. It is made of robust materials to protect the internal parts from external influences such as dust, moisture and mechanical damage. In addition, the housing ensures correct alignment of the components and contributes to the overall stability and longevity of the valve solenoid.

- Coil: The coil is wound from insulated copper wire and forms the centrepiece of the valve solenoid. When an electrical voltage is applied, current flows through the coil, generating a magnetic field. This magnetic field is crucial for the function of the valve solenoid, as it controls the movement of the armature.

- Ferromagnetic core: The ferromagnetic core surrounds the coil and serves as a magnetic conductor. It amplifies the generated magnetic field and ensures that the magnetic force is effectively transferred to the armature. The core has a special shape to close the magnetic circuit and maximise the efficiency of the valve solenoid.

- Armature: The armature is a movable component made of ferromagnetic material. It is pulled in the direction of the core by the magnetic field and causes the valve to open or close. The design of the armature enables precise and fast movement, which is crucial for the functionality of the valve solenoid.

- Return spring: The return spring ensures that the armature returns to its initial position after the current is switched off. This component ensures that the valve closes reliably when the solenoid is no longer active and contributes to the longevity of the system.

Valve solenoid applications

- Automation technology: In automated production lines, valve solenoids control pneumatic or hydraulic valves that ensure precise machine and robot movements.

- Automotive and commercial vehicles: Valve solenoids are used in automobiles to control fuel injectors, transmission systems and other components, thereby improving the efficiency and performance of the vehicle.

- Air conditioning technology: In heating, ventilation and air conditioning (HVAC) systems, valve solenoids control valves that ensure the flow of air and water for optimum temperatures and air quality.

- Medical technology: Valve solenoids are used in medical devices, such as infusion pumps or ventilators, to precisely control the flow of liquids or gases.

- Household appliances: In modern household appliances such as dishwashers and washing machines, valve solenoids control the water supply and drainage.

- Food and beverage industry: Valve solenoids are used to precisely control liquids in production and filling systems, guaranteeing a high level of hygiene and efficiency.

Control and regulation of valve solenoids

- Control of valve solenoids: Valve solenoids are controlled by electrical signals that activate the coil and generate a magnetic field. A control unit sends pulses to the valve solenoid to initiate its opening or closing. These signals can be generated manually or automatically via a programme or control software to achieve specific operating conditions.

- Control of valve solenoids: The control of valve solenoids can be supported by sensors that measure parameters such as pressure, flow or temperature. These sensors provide continuous feedback to the control unit, which adjusts the valve position in real time. This control ensures precise and dynamic adjustment of the valve with the help of the valve solenoid, which improves the efficiency and reaction speed of the overall system.

Environmental requirements valve solenoid

- Temperature range: Valve solenoids must be able to operate in a wide temperature range, typically from -40 °C to +150 °C, without compromising their performance. High operating temperatures can lead to overheating of the coil and impair the magnetic properties of the material, while very low temperatures can restrict the mobility of the armature.

- Protection classes: Depending on the application environment, valve solenoids are equipped with different protection classes (e.g. IP protection classes). These protection classes are crucial to protect the electrical and mechanical components from dust, moisture and other environmental influences and to ensure the long-term functionality and reliability of the valve solenoid.

Valve solenoid - Questions & Answers

What is the difference between a valve solenoid and a solenoid valve?

A valve solenoid is the electromechanical component that controls the movement of the armature and thus triggers the opening or closing of the valve. Solenoid valves, on the other hand, are complete units comprising both the valve solenoid and the mechanical parts of the valve, including the housing and seals. While the valve solenoid is responsible for the actual linear movement and is combined with a valve in the customer application, the solenoid valve offers a complete solution for controlling fluid flows in various applications, making it particularly versatile and efficient for customers.

How is the service life of valve solenoids ensured?

The service life of valve solenoids is ensured by high-quality materials and precise workmanship. For example, specially coated components are used to prevent corrosion and increase resistance to extreme temperatures. In addition, valve solenoids are subject to stringent tests to ensure their performance and reliability. Regular maintenance and proper integration into the overall system also help to maximise the service life of the valve solenoids.

Can valve solenoids be used in different environments?

Yes, valve solenoids are designed for use in various environments. They can be used in industrial applications, automation technology and in food and medical technology. They can be realised in various protection classes to protect them from dust, moisture and chemical influences. They are also available in different temperature ranges so that they can work reliably even under extreme conditions.

Can valve solenoids switch and control proportionally?

Valve solenoids can both switch and control proportionally, depending on their design and the control system used. Switching (On/Off) valve solenoids open or close the valve completely, while proportionally controlled valve solenoids can variably adjust the valve opening to precisely regulate the flow. This enables finer control, which is crucial in many applications.

Which control systems are available for valve solenoids?

Valve solenoids can be operated with various control systems, including digital controls, analogue signals and programmable logic controllers (PLCs). Some models offer the option of pulse width modulation (PWM) to optimise flow control. This enables precise adjustment of the valve opening and improves the efficiency of the system. The choice of control system depends on the specific requirements of the application and can be customised to achieve optimum results.