Linear solenoids

Linear solenoids are customised by Magnetbau Schramme and then produced in series. You can rely on our many years of experience and expertise to make your project a success.

Discover a diverse selection of different types of linear solenoids below.

Linear solenoids - Product details

Advantages & structure of linear solenoids

Magnetbau Schramme has been developing and producing linear solenoids in small and large series for a wide range of applications and industry sectors for half a century.

Linear solenoids are mainly used as actuators to generate linear or rotary movements.

A linear solenoid typically consists of a housing, a coil with electrical connections, a movable armature and an iron core. The functionality of a linear solenoid is mainly determined by the number of windings of the coil and the current strength, as these factors influence the magnetic force generated. In addition, the choice of material and the geometric design of the individual components are relevant for performance optimization and efficiency maximization.

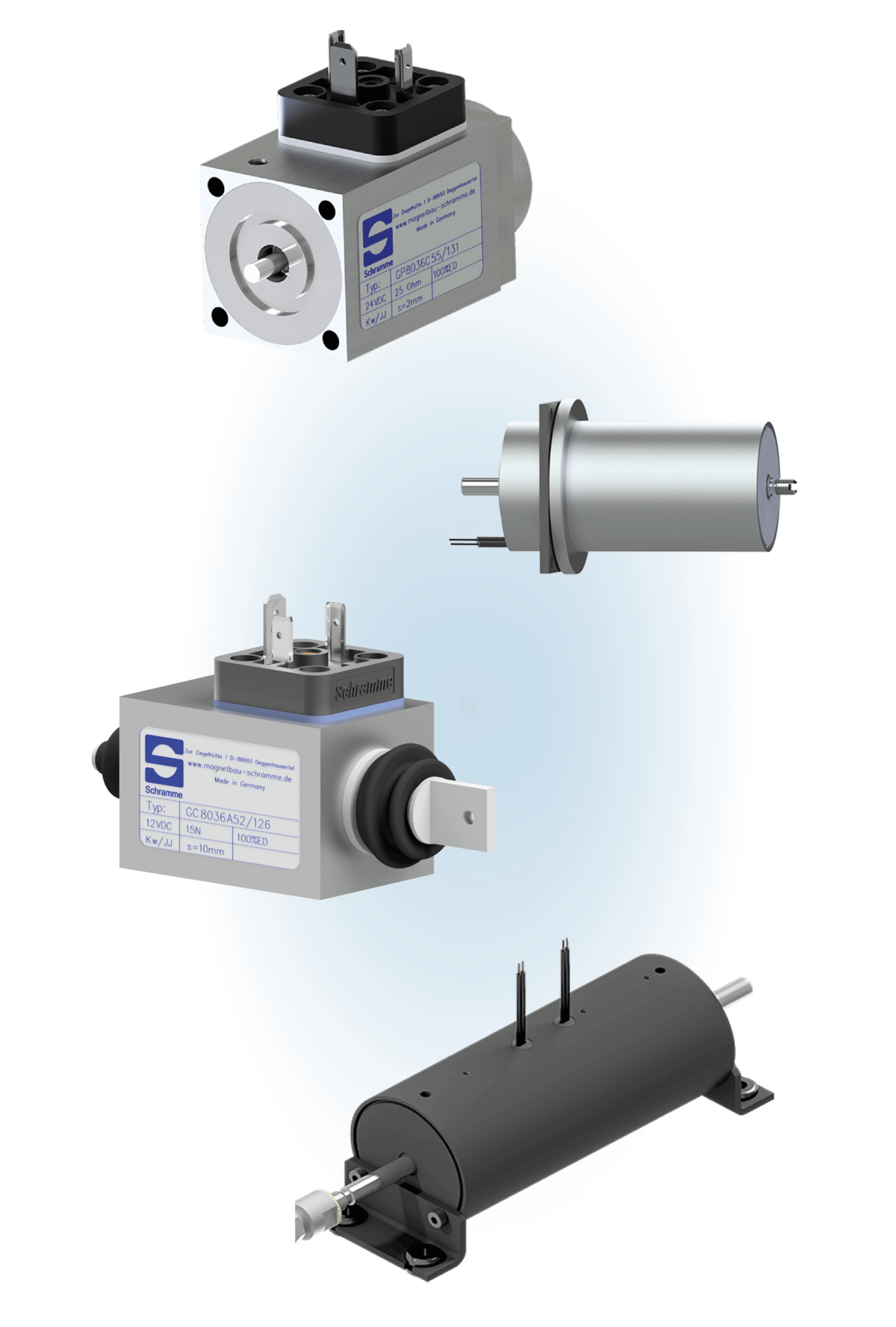

There are different types of linear solenoids: Proportional solenoids offer infinitely variable force and travel control and are ideal for precise control in valves and actuators. Switching solenoids enable fast on/off switching and are used in automation systems, for example. Reversing solenoids generate movements in both directions and are used in positioning systems, for example. Double-stroke solenoids enable two different stroke lengths and are useful in vehicle technology and conveyor systems, for example. Linear solenoids are widely used in areas such as medical technology, hydraulics and pneumatics and always help where precise and reliable control of movements is required.

Note

Please note that we do not have any standard products. The following linear solenoids are merely examples of customer projects realised in series.

Linear solenoids: Industry sectors

Our industry diversity

Linear solenoids are indispensable in numerous industry sectors: in safety technology, for example, they ensure reliable door closing mechanisms, while in commercial vehicles they help to support control systems. In medical technology, they regulate the movements of medical devices, and in the food industry they are used in sorting and packaging processes as well as for the precise dosing of various media.

Thanks to its expertise, flexibility and innovative strength, Magnetbau Schramme offers customised solutions for various industries. By precisely analysing the specific requirements, we develop linear solenoids that are precisely tailored to the needs of our customers.

Our management system according to ISO 9001 & IATF 16949 supports us in ensuring the quality requirements during the development & production of linear solenoids.

Marco Kiene

Management | CSO

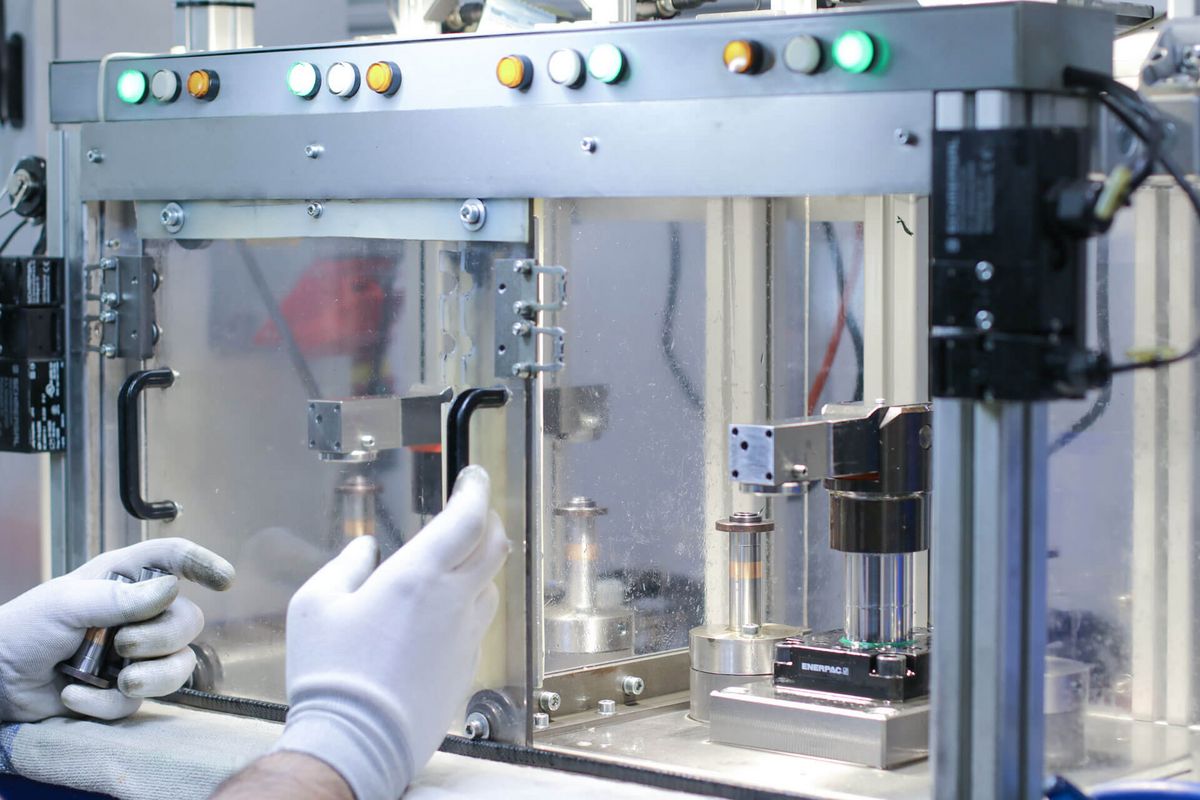

Application example: linear solenoid

Locking handling systems in injection moulding machines

A locking solenoid in a handling system of an injection moulding machine is used for the precise locking and interlocking of moving parts. Thanks to its electromagnetically generated stroke movement, it fixes components securely in a defined position or releases them in a targeted manner. This ensures reliable positioning and stability of the system during operation, thereby increasing process accuracy and safety.

More information about linear solenoids

A linear solenoid converts electrical energy into a linear mechanical movement. It consists of a coil, an iron core and a movable armature. When electric current flows through the coil, a magnetic field is created that pulls the armature in the direction of the core. This movement takes place along a defined axis and can be precisely controlled. If the current flow stops, the magnetism is interrupted. The armature returns to its starting position, often supported by a spring. This linear movement enables forces to be transmitted, components to be moved or mechanical circuits to be executed. The linear solenoid therefore offers a reliable and controllable mechanical function.

Structure of a linear solenoid

- Housing: The housing of a linear solenoid is usually made of ferromagnetic material, such as iron or steel. It encloses the magnetic core and the coil and guides the magnetic field by optimising the flow of the magnetic field lines and minimising the spread of the magnetic field in undesirable directions. The housing also protects the coil from external influences such as vibrations, moisture and mechanical damage.

- Coil: The coil of a linear solenoid consists of a wire winding, which is usually mounted on a coil former. The wire is typically made of highly conductive material such as copper. The number of windings, the current strength and the shape of the coil determine the properties of the magnetic field generated and therefore the functionality of the linear solenoid.

- Armature: The armature is the moving element of the linear solenoid which, when energised, aims to achieve the optimum state of the iron circuit. This minimises the working air gap and the armature moves in the direction of the iron core.

- Ironcore: The iron core is the fixed element in the linear solenoid towards which the armature is moved when the coil is activated. The iron core strengthens the magnetic field and improves the efficiency of the linear solenoid.

- Electrical connection: The electrical connection of linear solenoids is crucial for their reliable operation and safe integration into various systems. Depending on the specific application and design, different types of electrical connections are used.

Advantages of linear solenoids

A key advantage of linear solenoids is their impressive power. Compared to conventional permanent magnets, linear solenoids can generate significantly higher magnetic forces, which makes them ideal for applications that require a strong magnetic force.

Linear solenoids are also characterised by their versatility. They can be found in numerous applications, from industrial machines to entertainment systems, such as lifts, automated conveyor systems and various drive mechanisms.

Another plus point is the precise controllability of the linear solenoids. They can be activated quickly and accurately, making them suitable for applications that require fast and precise control of the magnetic force.

In addition, linear solenoids are extremely efficient as they only consume power when they are activated. In combination with permanent magnets, they can even be used in de-energised states.

Summary: What are the biggest advantages of electromagnetic systems and solenoid technology?

- Robust design and low sensitivity to interference

- Fast movement with high dynamics and large forces

- Low technical complexity compared to other technical solutions

- Simple electrical control

- Wide operating temperature range

- Small number of moving parts

- Long service life and no maintenance required

- High protection classes and explosion-proof products

- Can be used in a wide variety of areas

Linear solenoids - Questions & Answers

How are linear solenoids produced?

The production of linear solenoids begins with the winding of the coil, whereby copper wire is usually wound precisely around a coil former. The ferromagnetic armature, usually made of steel, is machined and brought to the required tolerances. The coil and armature are then installed in a housing, which is often made of metal or plastic to ensure mechanical stability. Finally, the connections and electrical contacts are assembled, followed by tests to check functionality and quality.

What is the difference between an electromagnet and a permanent magnet?

The difference between an electromagnet and a permanent magnet lies in the way in which the magnetic field is generated: An electromagnet only generates a magnetic field when an electric current flows through a wire coil, so that its magnetic field can be switched on and off and its strength can be varied. A permanent magnet, on the other hand, permanently generates a constant magnetic field without the use of electrical energy and cannot be switched off.

What maximum tensile or compressive force can the solenoid exert?

The maximum tensile or compressive force of a linear solenoid depends on its size, the coil current and the magnetic material quality. Typically, the forces range from a few newtons to several thousand newtons, depending on the application. The force decreases with increasing distance between the armature and the coil generating the magnetic field, which is why the maximum force is greatest within the coil.

How long does the linear solenoid last in continuous operation and what is its service life?

The service life of a linear solenoid depends on the operating frequency, load, ambient temperature and the quality of the materials used, and can range from a few thousand switching cycles to several hundred million switching cycles, depending on the area of application. In continuous operation, the service life can be limited by thermal loads and mechanical wear of the moving parts. Regular maintenance and the use of suitable cooling systems can extend the service life.

Can the linear solenoid be used in my specific environment, e.g. in high temperatures or humidity?

Yes, linear solenoids can be customised for specific environments by using heat-resistant materials and seals. For use in high temperatures or humidity, special models with protection ratings such as IP65 or higher must be selected to ensure reliable operation.

What voltages and currents does the solenoid require for operation?

Linear solenoids are typically designed for voltages from 12 V to 230 V, depending on the application and size, whereby both direct and alternating current variants can be realised. The required current varies between a few milliamperes and several amperes, depending on the desired magnetic force and the coil design. Higher voltages or currents generally lead to stronger magnetic forces, but also require customised control and safety systems.

How fast is the response time of the solenoid and how precise is the lifting movement?

The response time of a linear solenoid is typically in the millisecond range, usually between 10 and 100 ms, depending on the design and control. The precision of the stroke movement depends on the mechanical design and the control system, whereby tolerances in the range of fractions of a millimetre can be achieved. Specially customised models can be used for applications with high precision requirements.